What are the factors that affect EN10111 DD1 steel for cold forming automobile strength

Over the years, the company has established a standard of EN10111 DD1 steel for cold forming automobile steel products pre-sale, in sale and after-sale service, which meets customers' needs in all aspects and in the whole process, so that our product

Over the years, the company has established a standard of EN10111 DD1 steel for cold forming automobile steel products pre-sale, in sale and after-sale service, which meets customers' needs in all aspects and in the whole process, so that our products and services are deeply trusted by customers, and has established a long-term cooperation and mutual benefit relationship with customers. The company adheres to EN10111 DD1 steel for cold forming automobile quality surpervision, comprehensively implements quality management, strictly controls the whole process of product from contract signing to after-sales service.

A709Gr50 steel is a high-strength low-alloy stee. It is widely used in engineering structures, such as building steel structures, construction machinery, mining and mountain machinery, trucks, bridges, pressure vessels, especially for those requiring good weldability and toughness Construction and construction machinery parts. BBNsteel’s engineers suggest customer choose low temperature impacting test for steel A709 grade 50 at zero centigree, because these steel plates A709Gr50 normally used in this temperature.

Q215 steel has good plasticity and weldability. Q235 steel has certain strength, plasticity, toughness and weldability. Q235 steel is easy to punch and can meet the use of steel structure. Q255 steel has high strength, good plasticity and weldability, and its application is not as extensive as Q235 steel. Q275 steel has high strength, poor plasticity and weldability. Q275 steel is used for shafts, connecting rods, gears, keys and metal components with high strength requirements.

The composition characteristics of low alloy high strength steel are low carbon ≤0.20%, low alloy, and total alloying elements is less than 3%. The low carbon content is to meet the process performance requirements of EN10111 DD1 steel for cold forming automobile, low alloy high strength steel for engineering structural parts such as plasticity, toughness, weldability and cold deformation; adding a small amount of alloying elements (mainly Mn) to achieve the purpose of improving mechanical properties. Mn not only has a significant strengthening effect on ferrite, it can also reduce the cold brittle temperature of steel, increase the amount of pearlite in the steel, and further improve the strength.

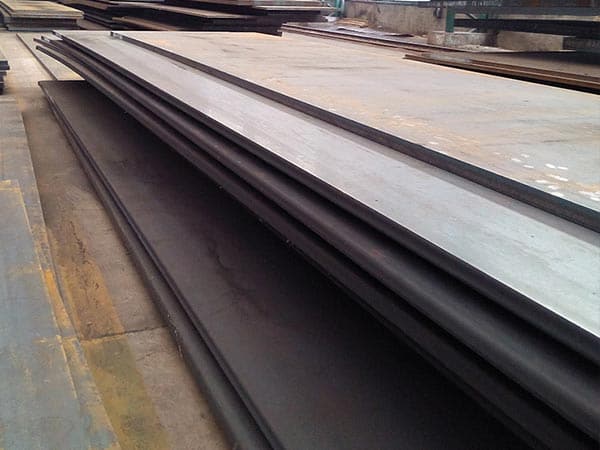

EN10111 DD1 steel for cold forming automobile, SS400 steel is one of the most commonly used hot rolled general structural steel. SS400 steel’s mechanical properties is yield strength more than 225-235MPa, tensile strength 360-510Mpa and 340-470Mpa. For SS400 steel, the C element content is 0.2% max, the Mn element content is 1.40% max, the P element content is 0.045% max, the S element content is 0.045% max.

Our company has strict quality control standards. If you want to visit our factory, you are welcome at any time! We produce a lot of steel products every month to export EN10111 DD1 steel for cold forming automobile to all over the world. Because our customers are from all countries, they will order a large number of steel products from our company every month.

We guarantee to provide all technical data required by users within one hour to provide reasonable quotation; to provide EN10111 DD1 steel for cold forming automobile reasonable quotation for products consulted by users within one hour; to provide investigation reception: we guarantee to receive the investigation of users at any time and provide various convenient conditions for users.

Leave a message