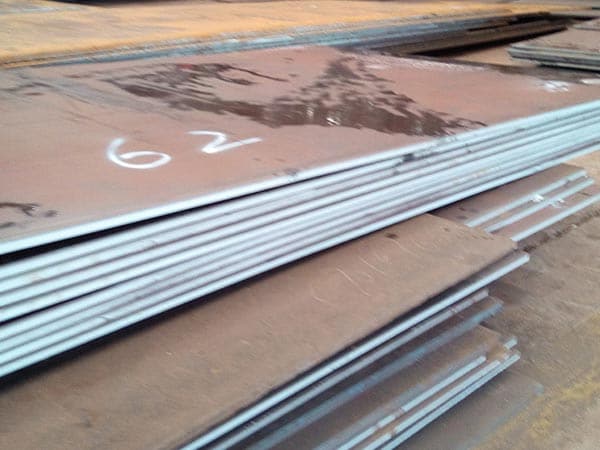

Alloy steel DD14 steel for cold forming automobile 1inch size stock

The company's DD14 steel for cold forming automobile steel products are sold all over the world with high quality and low price. We can process and cut all kinds of special-shaped parts according to your requirements, or we can set and roll futures o

The company's DD14 steel for cold forming automobile steel products are sold all over the world with high quality and low price. We can process and cut all kinds of special-shaped parts according to your requirements, or we can set and roll futures of all kinds of material specifications according to your requirements, with fast delivery time. We sincerely welcome new and old customers from all walks of life to contact us for DD14 steel for cold forming automobile business negotiation. With the enthusiasm, good reputation and professionalism of our staff, we will provide excellent services to our valued customers in all aspects, so as to achieve common development and prosperity.

The alloying elements of low alloy steel are less than 5%. The low alloy steel is added one or several alloy elements on the basis of carbon steel to improve the performance. Such as manganese, silicon, aluminum, nickel, copper, boron, phosphorus, rare earth, etc. DD14 steel for cold forming automobile Steel with one or more of these elements will have the advantages of high strength and toughness. Due to the addition of few alloy elements, it is called low alloy high strength steel.

40Cr steel plate is one of the most widely used steel in machinery manufacturing. After tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity. The hardenability of steel DD14 steel for cold forming automobile is good. It can be hardened to Ф28 ~ 60mm during water quenching and Ф15~40mm during oil quenching. When the hardness is HB174~229, the relative cutting workability is 60%. The steel is suitable for making medium-sized plastic molds.

Phosphorus element (P element) is brought into steel by ore. Generally speaking, phosphorus is also harmful element. Although phosphorus can increase the strength and hardness of DD14 steel for cold forming automobile etc. steel, it also causes the decrease of plasticity and impact toughness. Especially at low temperature, it makes steel significantly brittle, which is called "cold brittleness". The higher the phosphorus content is, the greater the cold brittleness is. Therefore, the phosphorus content in DD14 steel for cold forming automobile etc. steel is strictly controlled.

Seamless pipes material and specificationAPI 5L Gr.B, DD14 steel for cold forming automobile A106 Gr.B, ASTM A53 Gr.B, ST37.0, ST35.8, St37.2, St35.4/8,St42,St45,St52,St52.4, STP G38, STP G42, STS42STPT49STS49Sizes(mm): 0.12-2.0mm*600-1250mmWall Thickness(mm):1.2mm-40mmCertificates: API5L ISO 9001:2008 TUV SGS BV etcSurface: Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE

The strip steel thickness is generally below 6mm, which is convenient for crimping and processing. You should choose the DD14 steel for cold forming automobile, strip steel specifications according to your own purposes. The specifications and materials used for different purposes are different, so you must confirm it before buying. It is best to ask professionals to give advice before purchasing strip steel, and purchase the specifications and types you need according to the corresponding requirements.

Compared with other fast-moving consumer goods, steel consumption is obviously different, with a wide range of use and a long service life. Therefore, the quality and service of steel materials are particularly important. Service is always one of our top concerns, especially after-sales service. We have mature after-sales service team, and can help you solve problems professionally during application of the steel materials.

Leave a message