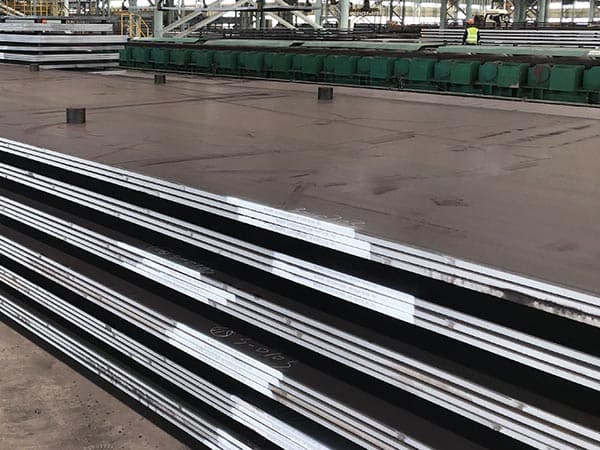

The width of EN 10149-2 steel coil is 500-1500mm

Customer service center has provided after-sales service for many large-scale information systems, and has accumulated rich working experience in the process of EN 10149-2 steel coil service for many years. It can provide accurate, timely and high-quality

Customer service center has provided after-sales service for many large-scale information systems, and has accumulated rich working experience in the process of EN 10149-2 steel coil service for many years. It can provide accurate, timely and high-quality support and service for users, which is well received by users.

S355J2 steel plate EN 10149-2 steel coil rolling process is controlled rolling process. In the rolling process, the ingot rolling temperature is 1000-1050℃; in the first stage, the low-speed and large reduction rolling process is adopted, the high-temperature stage is 950-1000℃, the rolling speed is 1.6-2.0m/s, the EN 10149-2 steel coil single reduction rate is 15-20%, and the cumulative reduction rate is 40-45%, so as to ensure sufficient deformation of ingot. In the first stage, the start rolling temperature is 910-930℃, and the finish rolling temperature is ≤ 870℃.

13CrMo4-5 seamless pipe is a kind of pressure resistant seamless pipe in accordance with the European standard EN 10216-2. The chemical composition of 13CrMo4-5 seamless pipe is C 0.10-0.17, Si ≤ 0.35, Mn 0.40-0.70, P ≤ 0.025, S ≤ 0.020, Cr 0.70-1.15, Ni ≤ 0.30, Mo 0.40-0.60, Al ≤ 0.04, Cu ≤ 0.03. Mechanical properties of 13CrMo4-5 seamless pipe: tensile strength: 440-590 MPa, yield strength: ≥ 290 MPa, elongation: ≥ 22%, impact energy: ≥ 40J. EN 10149-2 steel coil, 13CrMo4-5 seamless pipe is used in petroleum, chemical industry, power station, boiler and so on industries.

Safety production is the cornerstone of enterprise survival and development. The company established a safety management network, which achieved clear powers and responsibilities, clear responsibilities, effective management and control, and provided organizational guarantee for safe production. The company strictly complies with the "Environmental Protection Law", establishes an effective environmental protection emission control system and waste gas, waste water, waste solid recycling system, and makes great efforts to harden, lighten, green, and beautify the plant, and strive to build green steel enterprises.

Leave a message