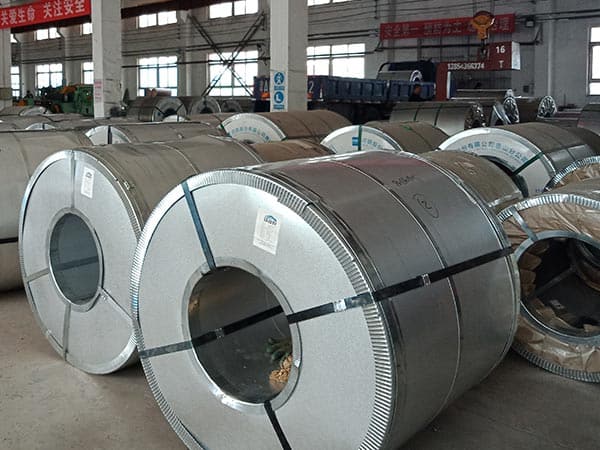

S550MC steel coil with Material Test Reports

Considering the large workload of allocation and transportion for our steel materials, we have built special shipping department, and make it independent form transportation department. The transportation department is in charge of transporting steel mate

Considering the large workload of allocation and transportion for our steel materials, we have built special shipping department, and make it independent form transportation department. The transportation department is in charge of transporting steel materials from our mill and warehouse to the port, and our shipping department is in charge of the shipping matters. So that our whole shipping efficiency is improved, and shorten time for customers to receive goods.

S550MC steel coil, Alloy plate is a steel plate with multiple uses because it has the following characteristics. First, better abrasion resistance. Alloy plate is more wear-resistant than ordinary steel plate. It does not scratch or wear, and has applications such as floor steel plate laying, steel plate wall and so on. Second, the alloy plate has higher strength. Third, the alloy plate is more resistant to high and low temperatures. Fourth, the alloy plate has outstanding corrosion resistance. As the steel laid on the ground, it must have good corrosion resistance. Because it will suffer from wind and rain for a long time, it must be very resistant, otherwise it will be damaged once it is corroded.

The company's headquarters has a well-established logistics distribution system, which can quickly transport the steel materials to the port through the contracted logistics companies. Professional contracted logistics companies can significantly reduce costs and various commodity-related expenses. Meanwhile, the flexible transfer ensures that the S550MC steel coil steel materials can be shipped immediately after passing the quality inspection.

keyword} product plate production process:Raw materials (scrap steel, pig iron and molten iron) → electric furnace (100 tons electric arc furnace smelting) → converter → LF furnace molten steel refining treatment → VD or VOD furnace molten steel vacuum treatment → die casting (various key die casting lines) or continuous casting (large Slab caster) (50 tons of slab electroslag furnace for remelting a steel ingot) → heating (continuous furnace and soaking furnace) → steel plate rolling (4100 and 4200mm rolling mills) → steel plate heat treatment (normalizing and tempering) Quality) →Steel plate cutting inspection→Inspection

Leave a message