Professional BS700MC cold forming steel sheet from BBN

The company is a leading steel production and exporting group in steel materials with advanced production technology, metal-cutting skill, and steel structures engineering projects. We can supply carbon steel plate and sheet, alloy steel plates and struct

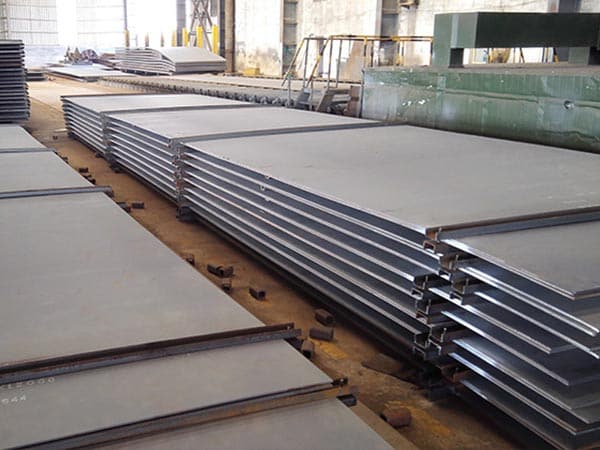

The company is a leading steel production and exporting group in steel materials with advanced production technology, metal-cutting skill, and steel structures engineering projects. We can supply carbon steel plate and sheet, alloy steel plates and structural BS700MC cold forming steel steel plates. These hot rolled steel plates are sturdy plates having high quality. Their imperviousness to effect and scrapped area, weld capacity, and workability make them a worthy product in a variety of industries.

BBN company team and culture: tt the end of 2019, in order to thank employees for their hard work and enrich their sparetime lives, the company organized a pleasant trip to Phuket Island, Thailand. This tour lasted 6 days and 5 nights, and returned by plane on the evening of December 27. We took off in Zhengzhou at about 5o'clock in the afternoon on the 22th December. Let's seize the day and live it to the full, and greet the arrival of the year 2020 together.

Wear resistant steel plate has high wear resistance and good impact performance. It can be cut, bent, welded, etc. Wear resistant steel plate can be connected with other structures by welding, plug welding, bolt connection, etc.. It is time-saving and convenient in the process of maintenance site. Wear resistant steel plate BS700MC cold forming steel is widely used in metallurgy, coal, cement, power, glass, mining, building materials, brick and tile industries. Compared with other materials, it has a high cost performance and has been favored by more and more industries and manufacturers.

The advantage of plasma cutting is that it can cut thin plates, stainless steel and non-ferrous metals, and the cutting speed is fast. The disadvantage of plasma cutting is that the incision will have a slope, and there will be noise when cutting. The advantages of water jet cutting are wide cutting range and environmental protection, but the disadvantages of water jet cutting are slow cutting speed and high energy consumption. Do you know what is the best cutting method for BS700MC cold forming steel?

In December of 2015, our regular India customer sent us an inquiry for BS700MC cold forming steel pipe. The inquiry requires no negative tolerance in both pipes’ outer diameter and pipe wall. After two weeks’ discussion, he put the order of 275 tons to us. The pipes are finished within just one month. Our customer come to our factory to inspect the quality and tolerance, all the products are well meet his demand. The pipes are arriving to Nhava Sheva port, customer is very happy with our products and service during the process.

Based on the principle of “sincerity and win-win cooperation”, our company keeps forging ahead. In the fierce market competition, we have won the trust and rapid development of our customers with good cooperation and sincere service spirit. With pioneering spirit, the pursuit of excellence, continuous learning, and never satisfied content, we will create a win-win situation with our customers to create a better future. The company has sufficient inventory and complete varieties and specifications.

Leave a message