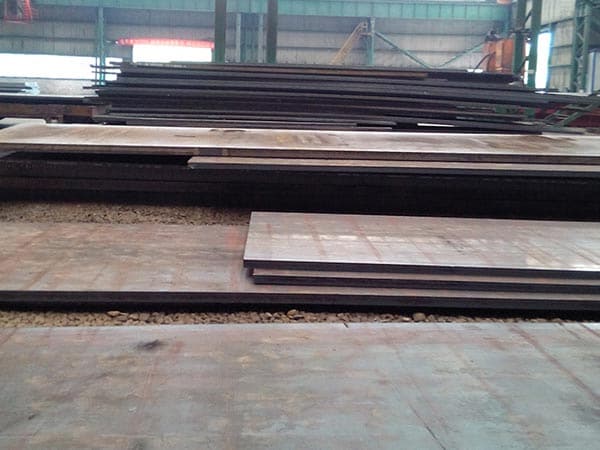

BBN steel S700MC cold rolled coil, steel structures stock

Our technical department plays important role in our professional communication with customers, especially those who have high technical requirements for steel materials and those who need complex further processing. Under such condition, our technician d

Our technical department plays important role in our professional communication with customers, especially those who have high technical requirements for steel materials and those who need complex further processing. Under such condition, our technician department can provide technical support in time, anylize customer design or make drawing according to customer needs rapidly, so that we can proceed smoothly. The profession of our team has won great praise of customers.

Our gas cylinder steel materials S700MC cold rolled coil are hot selling in 2019. The order quanitity for gas cylinder steel coils and sheets amount to 10,000 tons. Among them, a large portion of the gas cylinder steel coils and sheets are exported to Uganda, Kenya and so on Africa countries for gas cylinder production companies. Now our S700MC cold rolled coil gas cylinder steel has taken a large market share in local. We supply both gas cylinder steel coils and gas cylinder steel sheets. The dimension is customizable.

S700MC high-strength cold-formed hot-rolled steel sheet S700MC cold rolled coil more greatly improves the yield strength than traditional steel grades, and at the same time has good elongation performance, cold bending performance, welding performance and impact resistance. S700MC high-strength steel is mainly used for large ships, bridges, power station equipment, medium and high pressure boilers, high pressure vessels, rolling stock, lifting machinery, mining machinery and other large-scale welding structural parts.

"Efficiency is benefit, time is money", the company is equipped with a high standard logistics team. After the products pass the factory inspection, they will coordinate the shipment as soon as possible according to customer requirements and schedules to hand over the booked steel materials to customers at the first time, to ensure no delay of customer's project progress, to strive for more project preparation time for customers.

Weathering steel generally adopts the process route of fine material into the furnace-smelting (converter, electric furnace-microalloying treatment-argon blowing-LF refining-low superheat continuous casting (feeding rare earth wire)-controlled rolling and cooling. The scrap steel is added into the furnace together with the charge, and smelted according to the conventional process. After the S700MC cold rolled coil steel is tapped, deoxidizers and alloys are added. After the molten steel is treated with argon blowing, the molten steel is cast. By adding rare earth elements to the steel, the S700MC cold rolled coil weathering steel is purified and the content of inclusions is greatly reduced.

When providing technical services on site, the after-sales personnel shall strictly abide by the safety rules and regulations of the construction site, consciously take safety protection measures (such as wearing safety helmet when entering the construction site), accept the supervision and management of the site; without permission on the construction site, they shall not dismantle, smear or damage any goods; the commissioning of contract goods shall be carried out under the supervision of the site supervisor If necessary, it shall be approved by the site supervisor or the person in charge of the project department.

Leave a message