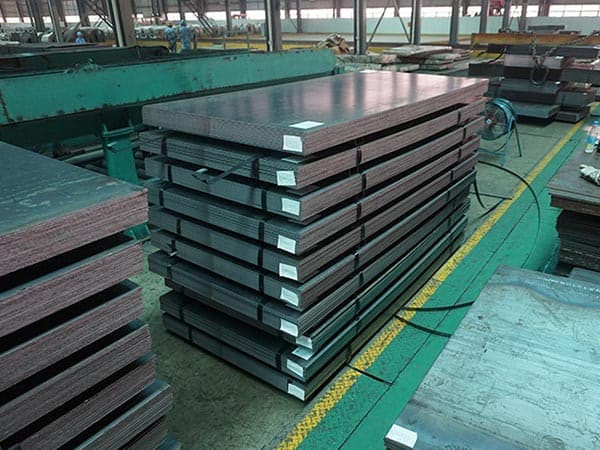

1/4 inch BS700MC weldable structural steel BBN steel stock

After more than 20 years of ups and downs in the steel industry, BBN company's customers have covered South America, North America, Europe, Africa, Southeast Asia and the Middle East and other countries and regions. We treat every customer who inquir

After more than 20 years of ups and downs in the steel industry, BBN company's customers have covered South America, North America, Europe, Africa, Southeast Asia and the Middle East and other countries and regions. We treat every customer who inquires with us sincerely, whether you cooperate with us or not, we will provide you with the best quality steel solutions. Our company team also support the online customer service.

Myanmar's demand for BS700MC weldable structural steel steel products is likely to exceed 3 million tons in 2020 and 5 million tons by 2025, according to seaisi. However, Myanmar's producers are unable to meet domestic demand, so the country's steel products are more dependent on imports. In 2019, Myanmar imported more than 1.9 million tons of BS700MC weldable structural steel finished steel, including 57% of long products, 13% of uncoated hot-rolled and cold-rolled flat products, and 30% of coated steel. In order to reduce its dependence on imports, Myanmar plans to increase its steel production capacity by building and expanding steel mills.

The main characteristics of BS700MC weldable structural steel, 12Cr1MoV alloy steel plate are as follows:Compared with 12CrMoV steel, 12Cr1MoV alloy steel plate has higher oxidation resistance and thermal strength. The creep limit of 12Cr1MoV steel is close to the stress rupture strength, and it has high plasticity under the condition of long-term tension. The process and weldability of 12Cr1MoV steel are good, but it needs to be preheated to 300 ℃ before welding, and stress relief treatment is required after welding.

Box making, door-to-door: fill in the packing plan: box making time, ship name, voyage number, customs declaration number, transfer port, destination port, gross weight, number of pieces, volume, door point, contact person, telephone number, etc., and arrange the train shift 1-2 days before the closing date (two days before the ship's date). Internal loading: fill in the packing plan: ship name, voyage number, customs declaration number, transfer port, destination port, gross weight, number of pieces, volume, cabin number, etc., and arrange the train shift 1-2 days before the closing date (two days before the ship's date).

Penetration testing technology is only suitable for detecting surface defects. It uses penetrant to apply on the surface of the BS700MC weldable structural steel steel plate, then wipes the excess penetrant with the cleaning solution, and then smears the developer. The penetrant remaining in the defect is adsorbed by the developing material, so as to observe the shape of the defect and determine the type of defect. This BS700MC weldable structural steel method requires multiple wipes before and after the inspection, the process is more cumbersome, and can not detect internal defects and rough and dirty steel plates.

The company formulates clear service process and service standard. To do a good job in after-sales service, first of all, clear service process and service standards should be formulated to let employees know which procedures to perform and which service standards to abide by.

Leave a message