High quality s500 steel equivalent

Our technical department plays important role in our professional communication with customers, especially those who have high technical requirements for steel materials and those who need complex further processing. Under such condition, our technician d

Our technical department plays important role in our professional communication with customers, especially those who have high technical requirements for steel materials and those who need complex further processing. Under such condition, our technician department can provide technical support in time, anylize customer design or make drawing according to customer needs rapidly, so that we can proceed smoothly. The profession of our team has won great praise of customers.

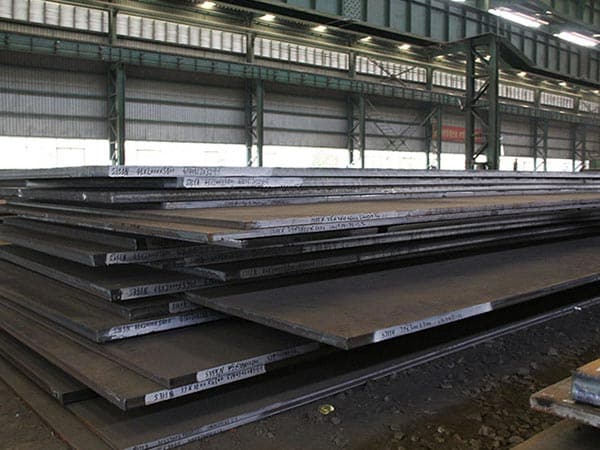

Low alloy coils are steel coils made of steel with a low alloy content, usually less than 3.5%. Low alloy coil materials mainly include A572 Gr 50, s355jr, SS490, ST52-3, Q345B, etc.. These grades are also the most widely used and produced low-alloy high-strength steel grades in the world. The strength of low alloy coils is about 20% to 30% higher than that of ordinary carbon structural steel, S500 steel equivalent. And the atmospheric corrosion resistance of low alloy coils is 20% to 38% higher than that of ordinary carbon structural steel.

s500 steel equivalent, Low alloy steel plate is a general designation, mainly refers to the steel plate with alloy content less than 3.5%. Alloy steel in the market is distinguished by the total amount of alloy elements, mainly including low alloy steel, medium alloy steel and high alloy steel. When the total alloy amount is less than 3.5%, it is called low alloy steel; if the total alloy amount is 5-10%, it is medium alloy steel; and when the total alloy amount is more than 10%, it is high alloy steel.

Preheating cutting: The most effective way to prevent steel plate cutting cracks is to preheat before cutting. Before flame cutting, the steel plate is usually preheated, and the preheating temperature mainly depends on the quality level and thickness of the steel plate. The preheating method can be carried out with flame burner, electronic heating pad, or heating furnace. In order to determine the preheating effect of the steel plate, the required temperature should be tested at the heating point.

We have a professional after-sales service team, the company has developed a clear service process and service standards, after-sales service team members strictly perform after-sales procedures, comply with service standards. The most important thing is that we have set up the correct concept of after-sales service, "customer first, sincere service for users".

"Hard and solid, honest commitment, practical effect". To strive for a solid enterprise foundation with hard work style; to promise first-class enterprise service with honest faith; to create efficient enterprise performance with practical spirit.

Leave a message