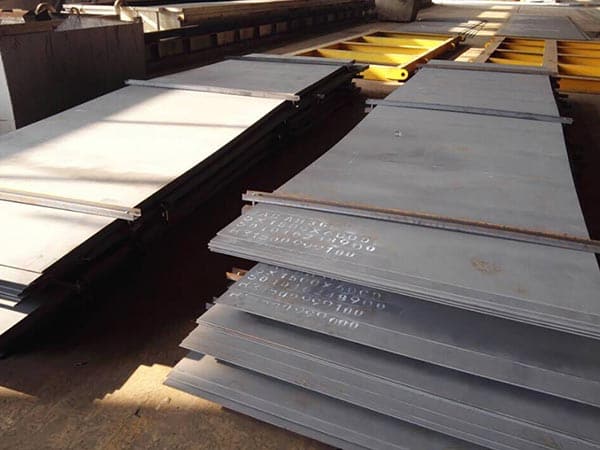

Standard number of en 10149-2 s315mc steel for auto frame

Focusing on the energy conservation and emission reduction objectives proposed by the municipal government, the company gives full play to the advantages of en 10149-2 s315mc steel for auto frame circular economy formed after the comprehensive completion

Focusing on the energy conservation and emission reduction objectives proposed by the municipal government, the company gives full play to the advantages of EN 10149-2 S315MC steel for auto frame circular economy formed after the comprehensive completion and operation, and vigorously promotes the implementation of energy conservation objectives. Through measures such as energy saving, technological innovation and en 10149-2 s315mc steel for auto frame management strengthening, the energy saving target of annual reduction of added value energy consumption by 7%. It has made great contribution to energy saving of over completion.

S355J2+N steel plate belongs to the European standard low alloy structural steel grade. S355J2 steel is equivalent to Q345D grade. en 10149-2 s315mc steel for auto frame, S355J2+N low alloy steel plate is widely used in bridges, vehicles, ships, building steel structures. Mechanical properties of S355J2+N steel: Yield strength: ≤16mm: ≥355; 16-40: ≥345; 40-63: ≥335; 63-80: ≥325;80-100: ≥315; 100-150: 295; 150-200: ≥285; 200-250: ≥275; 250-400: ≥265. Tensile strength: 450-680MPa.

20G steel is a common carbon steel used to manufacture boilers. The performance of 20G steel is basically the same as that of 20# steel. The requirements for impact toughness, strain aging impact value and cold bending of 20G steel are increased. The yield ratio of 20G steel is slightly higher, and certain fatigue and corrosion resistance are required for en 10149-2 s315mc steel for auto frame steel to ensure the safe operation of boilers. 20G steel is suitable for manufacturing marine boilers, steam boilers and other boiler accessories with pressure less than 6Mpa and wall temperature less than 450 ℃.

The heat treatment process can significantly improve the physical properties of steel, improve the compressive strength, ductility and service life of parts, and improve the hardness and wear resistance. Therefore, critical equipment parts and special tools must be quenched and tempered. The quenching and tempering treatment can also improve the production and processing performance of the en 10149-2 s315mc steel for auto frame product workpiece, thereby improving the production efficiency and production processing quality.

The chemical composition difference between en 10149-2 s315mc steel for auto frame, Q235B and 20# steel is as follows: The chemical composition of 20# steel: C: 0.17-0.23%, Si: 0.17-0.37%, Mn: 0.35-0.65%, Cr: ≤ 0.25%, Ni: ≤ 0.30%, Cu: ≤ 0.25%. Chemical composition of Q235B steel: C: ≤ 0.20%, Si: ≤ 0.35%, Mn: ≤ 1.40%, P: ≤ 0.045%, S: ≤ 0.045%. The difference of mechanical properties between en 10149-2 s315mc steel for auto frame, Q235B and 20# steel is as follows: The mechanical properties of 20# steel: tensile strength 410 MPa; yield strength 245 MPa; elongation after fracture: 25; reduction of area: 55; no impact. Q235B steel mechanical properties: tensile strength 370-500 Mpa; yield strength: ≥ 235 Mpa; elongation after fracture: 25; impact absorption energy: 27J.

We have a professional after-sales department to collect all information related to customers, so as to make relevant treatment in time according to the information, and file it; guide the user's product use methods and precautions; coordinate with the sales department, visit customers regularly, understand the customer's use and new requirements, and make a customer visit record; When communicating with customers, they should be enthusiastic and careful to understand the situation of product problems and put forward solutions

Leave a message