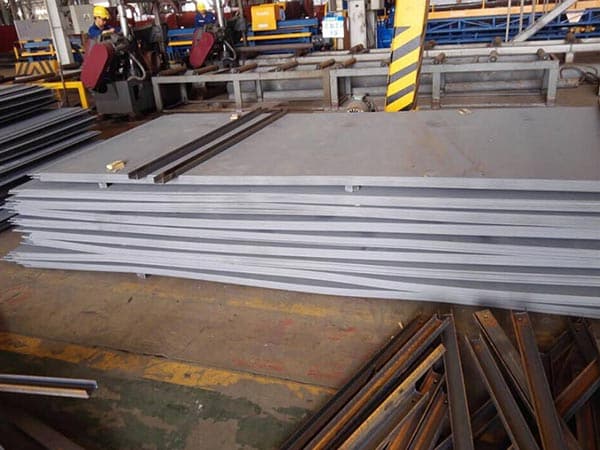

Special thick 1.8969 high yield strength alloy quality steel supplier

Under the specification EN 10025-2, S275J2 plates are mainly used in the building industry and mechanical engineering, containers,storage tanks and roll formed steel profiles,such as steel angles, steel structures, H-beams, T-sections. For 1.8969 high yie

Under the specification EN 10025-2, S275J2 plates are mainly used in the building industry and mechanical engineering, containers,storage tanks and roll formed steel profiles,such as steel angles, steel structures, H-beams, T-sections. For 1.8969 high yield strength alloy quality steel, S275J2 carbon steel, our engineers still suggest done normalized heat treatment for them if customers want to improve their steel's property when using. Else, this steel must be done low temperature impacting test at -20℃.

The company adheres to the 1.8969 high yield strength alloy quality steel external market, internal management, quality and efficiency oriented development path, and has achieved good economic and social benefits. With strong financial strength, advanced management experience, excellent sales service, strict quality management system and scientific overall marketing means, we will work hand in hand with you for common development. We are making all efforts working on the optimization of 1.8969 high yield strength alloy quality steel quality and price and best service for all our customers.

Our company has the ability to produce all kinds of steel structure parts. At the same time, we can design drawings according to the requirements of customers, and process according to the drawings. 1.8969 high yield strength alloy quality steel Heat treatment services - such as annealing, normalizing, quenching, tempering, quenching and tempering, solution treatment, etc. We can also heat treat according to customer's 1.8969 high yield strength alloy quality steel requirements.

1.8969 high yield strength alloy quality steel, Hot rolled seamless tube is usually produced on automatic tube rolling mill. After the solid tube blank is inspected and the surface defects are removed, it is cut to the required length, centered on the end face of the piercing end of the tube blank, then sent to the heating furnace for heating, and perforated on the piercing machine.

We have a professional after-sales service team, the company has developed a clear service process and service standards, after-sales service team members strictly perform after-sales procedures, comply with service standards. The most important thing is that we have set up the correct concept of after-sales service, "customer first, sincere service for users".

Leave a message