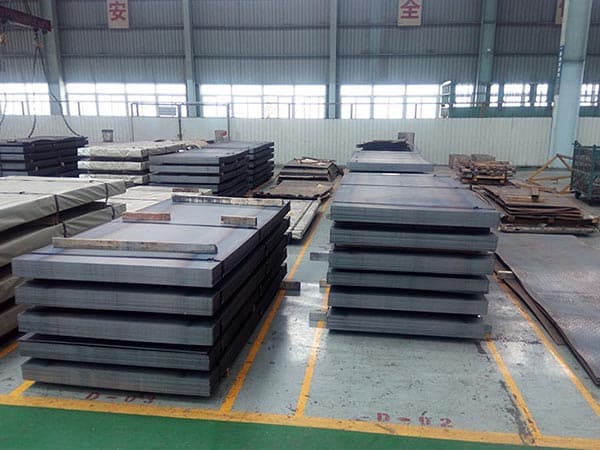

Factory supply S315MC steel for cold forming parts specification

In line with the service concept of "honesty first, customer first" and the service tenet of "all for customer satisfaction", the company adopts the acceptance and response mode of combining manual and automatic, and accepts the divers

In line with the service concept of "honesty first, customer first" and the service tenet of "all for customer satisfaction", the company adopts the acceptance and response mode of combining manual and automatic, and accepts the diversified service demands of customer business consultation, complaint declaration, business acceptance, etc. through telephone, fax, e-mail, visit, letter, etc.

S315MC steel for cold forming parts, NM450 wear-resistant steel plate has a Brinell hardness of 450HB. It has outstanding cold bendability and is mainly used in anti-wear conditions. NM450 wear-resistant steel plate has very good weldability. NM450 wear-resistant steel plates are used in dump truck carriages, containers, crushers, screens, feeders, feeding hoppers, elevators, blades, conveyors, buckets, blades, gears, sprockets, etc.

S355J2 steel plate yield strength Rp0.2≥265mpa, tensile strength RM: 450-680mpa, elongation a≥12%, impact energy Kv2≥27J, tensile area shrinkage Z≥35% in thickness direction. S315MC steel for cold forming parts, S355J2 steel plate has good internal quality, high density and stable performance.Meaning of S355J2-Z35: J2 requires negative 20 degree impact, and Z35 is the Z-direction performance of S355J2 steel plate.The meaning of S355J2 + N-Z35: J2 requires negative 20 degree impact, N means normalizing rolling rather than normalizing. Z35 is the Z-direction performance of S355J2 steel plate, S315MC steel for cold forming parts.

DC53 mold steel has better machinability and abrasiveness than SKD11. DC53 cold work die steel S315MC steel for cold forming parts is widely used in punching die, cold work forming die, cold drawing die; forming roll, punch; precision stamping die; precision cutting die for wire cutting and punching die for various purposes; difficult to process materials Tools for plastic deformation; cold forging, deep drawing and thread rolling dies; high-speed punching punches, stainless steel punches.

The after-sales service department will pay return visit to each customer by call or email, report problems found during the return visit in time, and discuss with the production and quality inspection center to propose effective solutions and follow up in a timely manner, so as to ensure the benefits each customer are fully guaranteed, and to provide customers with more value-added services.

Welcome customers to visit our company, we specialize in steel products, adhere to the S315MC steel for cold forming parts quality first standard, and do not forget to provide customers with the best quality products and services. Our product quality office is the best, and our S315MC steel for cold forming parts price is also very advantageous. Welcome to purchase steel products from our company.

Leave a message