Alloy structral s700mc steel equivalent in india with 16 thickness

SA516 grade 55, SA516 grade 60, SA516 grade 65, SA516 grade 70. These four grades s700mc steel equivalent in india are mainly defined by different tensile and yield strength ranges, which are affected by carbon content.Based on the s700mc steel equivalent

SA516 grade 55, SA516 grade 60, SA516 grade 65, SA516 grade 70. These four grades S700MC steel equivalent in india are mainly defined by different tensile and yield strength ranges, which are affected by carbon content.

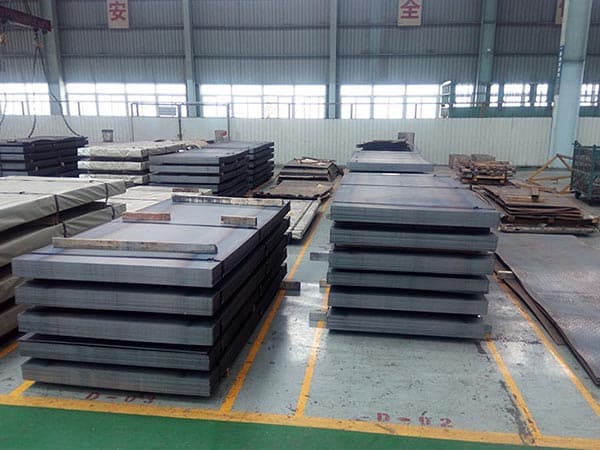

Based on the s700mc steel equivalent in india steel trade, the company mainly deals in Baosteel products: color coating, zinc plating, fingerprint resistance, cold rolling, hot rolling, pickling, electrical steel and other products, and can order the futures of the company's products on behalf of manufacturers. It has established cooperative relations with more than 2000 foreign customers. At the same time, it also operates a variety of products of related iron and steel enterprises. Annual sales of s700mc steel equivalent in india steel 3.6 million tons, standing stock of 400000 tons, has developed more than 10000 users. The company has a first-class marketing service system, strong storage and transportation capacity and supporting supply, cutting distribution capacity, and gradually build it into an important marketing channel.

At present, the cutting thickness limit of laser cutting is 20 mm. However, it should be noted that oxygen will be added into the laser beam to cut 20 mm thick s700mc steel equivalent in india steel plate, which will form a thin oxide film on the cutting surface, which may affect the cutting quality, Therefore, attention should be paid to this point to avoid problems.

The final heat treatment of quenched and tempered alloy steel, s700mc steel equivalent in india is quenching and high temperature tempering. The hardenability of quenched and tempered alloy steel is high, and oil is generally used. When the hardenability is very high, it can even be air cooled, which can reduce the defects of heat treatment. The final properties of quenched and tempered alloy steel depend on tempering temperature. Generally, it is tempered at 500 ℃ - 650 ℃. The required properties can be obtained by selecting tempering temperature. In order to prevent the second kind of temper brittleness, fast cooling (water cooling or oil cooling) after tempering is beneficial to the improvement of toughness.

After sales service support personnel pay attention to commitment in their work. In the process of people to people communication, mutual trust is an important factor for the long-term and stable communication. After sales service personnel must do what they say in the process of communication with customers.

Leave a message