6mm and 8mm thick B750L structure steel for cold forming price

The company covers an area of 15,000 square meters and the plant construction area is 10,000 square meters. We have introduced more than 50 sets of advanced B750L structure steel for cold forming production equipment, auxiliary equipment and testing equip

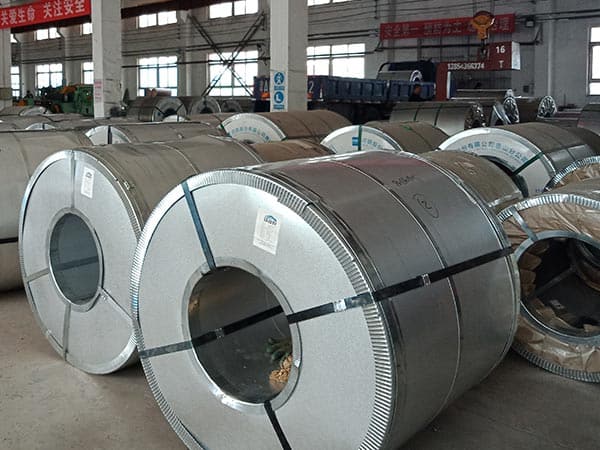

The company covers an area of 15,000 square meters and the plant construction area is 10,000 square meters. We have introduced more than 50 sets of advanced B750L structure steel for cold forming production equipment, auxiliary equipment and testing equipment at home and abroad, more than 260 employees, more than 20 middle and senior management staff, more than 10 professional and technical personnel, annual production capacity of 100,000 tons. Main products: flat steel, B750L structure steel for cold forming steel pipe, steel plate, section steel, steel structure processing parts, etc. We also accept incoming materials and annealing processing.

Booking space and making power of attorney (ten copies of order); the data of the original order shall be correct and consistent to the greatest extent when making the order, so as to reduce the frequent changes in the subsequent process. For booking with the company's seal for booking space, if the accessories for booking space (such as the price confirmation document of the shipping company) need to be provided, they can only be booked with all of them. Obtain the shipping space allocation receipt and extract the ship name, voyage number and B / L number information.

In the welding process, effectively preventing the stress and deformation of the component during the welding process is the key to ensuring the welding quality of the wear-resistant steel plate. In the welding process, after spot welding each part according to the position of the drawing, ensure that the size is consistent with the drawing. The welding method of symmetrical multi-layer multi-pass welding is adopted to ensure the appropriate welding process parameters, which can effectively prevent the welding deformation of the B750L structure steel for cold forming, wear-resistant steel plate.

In year 2015, we supplied 950 tons S355J0 angle steel to Egypt government. We have cooperation with local government for more than 3 years. Every year, they would order more than 3000 tons of B750L structure steel for cold forming steel from our company.

Asme sa514 grade B quenched and tempered alloy steel element composition%C: 0.12-0.21, Si: 0.20-0.35, Mn: 0.70-1.00, P max.: 0.035, S max.: 0.035, B max.: 0.005, Cr: 0.40-0.65, Mo: 0.15-0.25, V: 0.03-0.08, Ti: 0.01-0.03The mechanical properties in thickness (mm)T≤65Yield strength (≥Mpa): 690Tensile strength (Mpa):760-895Elongation in ≥,%: 18

Insist on the spirit of development and indomitable entrepreneurship; the spirit of leading science and technology and striving for first-class affairs; the spirit of strict management and market development; the spirit of taking the lead in setting an example and selfless dedication; and the spirit of people-oriented and enterprise ownership.

Leave a message