What is the difference between S700MC hot rolled coil yield strength sheet & plate steel?

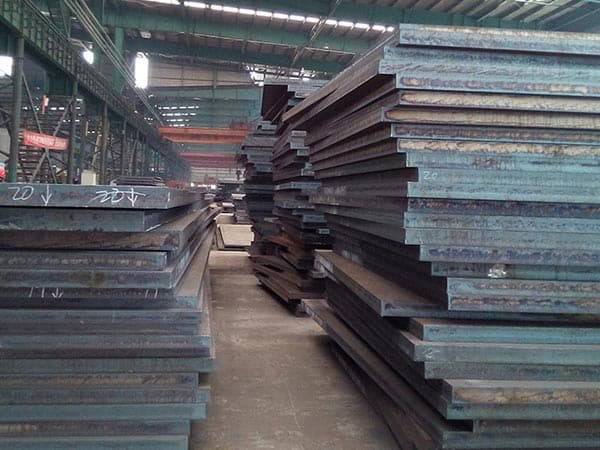

Based on the main business of iron and steel, we are committed to producing high-quality, green and efficient steel products. The main steel products are medium and S700MC hot rolled coil yield strength heavy plate, hot rolled coil, section steel, steel t

Based on the main business of iron and steel, we are committed to producing high-quality, green and efficient steel products. The main steel products are medium and S700MC hot rolled coil yield strength heavy plate, hot rolled coil, section steel, steel tube, etc., which are widely used in automobile, oil, railway, bridge, construction, electricity, transportation, machinery, shipbuilding and other important fields. Our steel products are exported S700MC hot rolled coil yield strength to Indonesia, Bangladesh, Myanmar, Iran, Brazil, Mexico, UAE, Iraq, etc Egypt, Mozambique, Ukraine and other dozens of countries and regions.

The company mainly supplymild S700MC hot rolled coil yield strength steel plate, alloy steel plate, boiler plate, corten steel plates for railway, marine, automotive, home appliances, shipbuilding, construction, machinery manufacturing and oil tank projects. While accelerating the development of the main steel industry, the company adheres to a diversified development strategy and actively develops the other industry like household products, face mask machine, precision casting producing, steel structures, and heavy plates processing service.

Corrosion resistant steel prices are generally higher. What are the applications of S700MC hot rolled coil yield strength, corrosion resistant steel? First, the corrosion resistant steel can be used in chemical containers, such as furnaces. Some chemical products have strong corrosivity and need steel with excellent corrosion resistance, otherwise they will be easily corroded. Second, the corrosion resistant steel can be used for sewage pipelines. Industrial sewage pipelines need to discharge a large amount of wastewater, which may contain harmful substances.

The strengthening mechanisms in metals mainly include solid solution strengthening, dislocation strengthening, fine grain strengthening, and second phase (precipitation and dispersion) strengthening. Alloying elements have the most significant strengthening effect on steel in the quenched and tempered state, because it makes full use of all four strengthening mechanisms. Martensite is formed during quenching, and carbides are precipitated during tempering, resulting in a strong second phase strengthening and greatly improving toughness. Therefore, obtaining martensite and tempering it is the most economical and effective comprehensive strengthening method for S700MC hot rolled coil yield strength.

EN10149-2 S315MC pickling plate chemical composition (melting analysis)%C: ≤0.12, Si: ≤0.50, Mn: ≤1.3, P: ≤0.025, S: ≤0.020, Ait: ≥0.015, Nb: ≤0.09, V: ≤0.20, Ti: ≤0.15Mechanical propertiesYield strength MPa: ≥315Tensile strength MPa: 390-510Elongation: ≥21

Our focus on quality has helped us create an efficiently organised production system, which can supply large-scale piping orders as well as tailor-made orders for smaller clients. We have also created a sales and support network which stretches from Asia to Europe, UAE, South Africa and South America.

Adhere to the spirit of quality first and user foremost, carry out maintenance and other work according to the requirements of the buyer's contract, and ensure that the engineering project and product after-sales play their application effectiveness. Our company guarantees to carry out self inspection and self supervision according to the quality management policy proposed by our company, and deliver a high-grade, perfect and excellent system engineering to users.

Leave a message