Why is S900MC cold forming autobobile steel more expensive?

Standing at a new historical starting point, we adapt to the requirements of supply side S900MC cold forming autobobile steel structural reform, adhere to the overall strategy of "innovation driven, quality leading, quality improving and efficiency i

Standing at a new historical starting point, we adapt to the requirements of supply side S900MC cold forming autobobile steel structural reform, adhere to the overall strategy of "innovation driven, quality leading, quality improving and efficiency increasing, transformation and development", and constantly improve the development concept and development level with a forward-looking vision and grand vision. Now we have been ranked the International leading S900MC cold forming autobobile steel steel materials supplier.

Pipeline steel refers to a type of steel with special requirements used for the transportation of oil, natural gas and other pipelines. Depending on the thickness and subsequent formation, pipeline steel can be produced by hot continuous rolling machines, furnace coil machines or plate machines, and formed into large-diameter steel pipe by spiral welding or UOE straight seam welding. The current development trend of S900MC cold forming autobobile steel pipeline engineering is large-diameter, high-pressure rich gas transportation, high cold and corrosive service environment, and thickening of submarine pipelines.

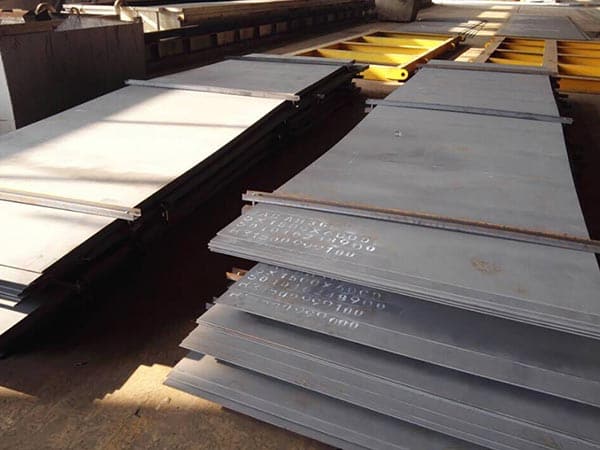

In the face of domestic and foreign steel situation, based on the advantages of production and inventory, we have established our own processing center, and our manufacturing includes different types. Steel S900MC cold forming autobobile steel surface treatment - such as steel pretreatment (shot peening and shop primer), steel galvanizing; steel structure processing - such as cutting, drilling, milling, turning, bending, welding, etc.

When phosphorus, copper, chromium, nickel and other trace elements are added to the steel, S900MC cold forming autobobile steel, a dense and strong adhesive protective film will be formed on the steel surface, which will prevent the corrosion from spreading and developing inward, and protect the substrate under the rust layer, so as to slow down the corrosion rate. The amorphous spinel oxide layer of about 50 μ m ~ 100 μ m thickness formed between the rust layer and the substrate is compact and has good adhesion with the substrate metal.

S900MC cold forming autobobile steel, HP265 steel with the thickness range is 1.2-12mm. HP265 steel’s mechanical properties is include the yield strength more than 265MPa, tensile strength is 410-520MPa. The chemical composition of HP265 steel is C element content is 0.18, the Si element content is 0.10, the Mn element content is 0.80, the P element content is 0.025% max, the S element content is 0.015% max.

Analyze the advantages and disadvantages of the products against the competitive S900MC cold forming autobobile steel products. Understand the industry situation and future trend. Understand the product brand positioning appeal point, focus on the crowd and development direction. Understand the layout of each market area, and form a big strategic layout view. Understand the basic operation and assessment standards of work responsibilities. Understand the situation of the cooperative customers.

As one of the large professional metallurgical manufacturers in China, the strength of the brand, quality assurance, professional after-sales. Every day we are making unremitting efforts to challenge higher quality S900MC cold forming autobobile steel products and more satisfactory services. Customer demand is our pursuit, and win customer satisfaction with quality. BBN after-sales team is responsible to solve the problem of technical support and quality, service complaints.

Leave a message