What is the best quality structure steel plate s700m?

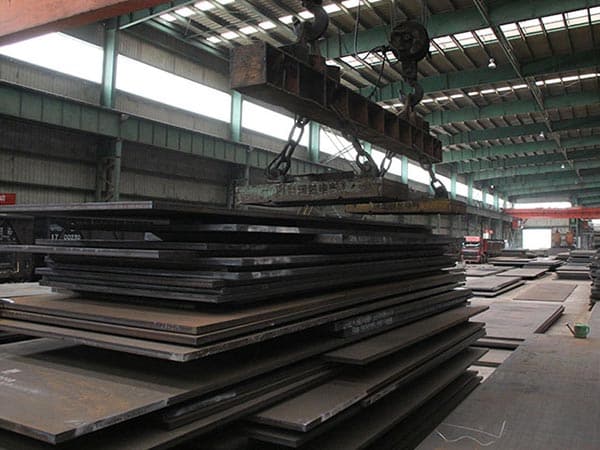

With high-quality structure steel plate s700m steel and professional services, we have won international praise in infrastructure, shipbuilding, oil and other industries, and gradually grow into a bright star in the steel export industry, while winning un

With high-quality structure steel plate s700m steel and professional services, we have won international praise in infrastructure, shipbuilding, oil and other industries, and gradually grow into a bright star in the steel export industry, while winning unanimous praise from foreign customers. It has laid a foundation for the development of our structure steel plate s700m steel market and improved the control of steel plate production quality.

The company operates Henan metallurgical rolling iron and steel factory all year round, providing steel products for various industries such as ow alloy high strength series, boiler and pressure vessel steel plate, power station engineering steel plate series, structure steel plate s700m bridge structure steel plate, corrosion resistant steel plate, composite steel plate, high-rise building structure, die steel plate series, steel plate series for shipbuilding and offshore platforms, pipeline steel plate, alloy structure and other steel plates.

Wear resistant steel plate has high wear resistance and good impact performance. It can be cut, bent, welded, etc. This material structure steel plate s700m can be connected with other structures by welding, plug welding, bolt connection, etc. Wear resistant steel plate has the advantages of saving time and convenience in the process of maintenance. It is widely used in metallurgy, coal, cement, electric power, mining, building materials and other industries. Compared with other materials, wear resistant steel plate has a high cost performance, and has been favored by more and more industries.

The wear-resistant composite plate, structure steel plate s700m should be pre heat treated to eliminate the residual stress produced in the machining process. If conditions permit, vacuum heating quenching and cryogenic treatment after quenching should be selected as far as possible. On the premise of ensuring the hardness of steel plate, pre cooling, step cooling and quenching or high temperature quenching should be selected as far as possible. For some wear-resistant composite plates, pre heat treatment, aging heat treatment and quenching, tempering and nitriding heat treatment can be used to control the accuracy of the wear-resistant composite plate.

QSTE380TM material is a cold-formed hot-rolled pickled automotive structural steel.chemical compositionC: ≤0.12, Si: ≤0.35, Mn: ≤1.40, P: ≤0.03, S: ≤0.025, Alt: ≥0.01Mechanical propertiesYield strength MPa: ≥380Tensile strength MPa: 450-590Elongation: ≥23

We have a good inventory system because of which the alloy steel plates and structural steel sheets are supplied and delivered to our customers on time. Our alloy steel plate is significantly affordable than austenitic structure steel plate s700m stainless steel which helps to reduce maintenance and full life costs – as well as improved safety over standard boilerplate. Contact us today to request a quotation or email us with your complete specification, we are happy to help you!

Since its establishment, the company has been deeply supported and loved by customers with its unique business philosophy and business model. The company has always adhered to the tenet of "credibility first, integrity-based, quality first" and sincerely serves new and old customers. At the same time, it keeps pace with the times based on market orientation, continuously expands offline channels, and gradually establishes a complete online E-commerce business management platform. We will always promote our after-sales service to make client satisfied with our goods.

Leave a message