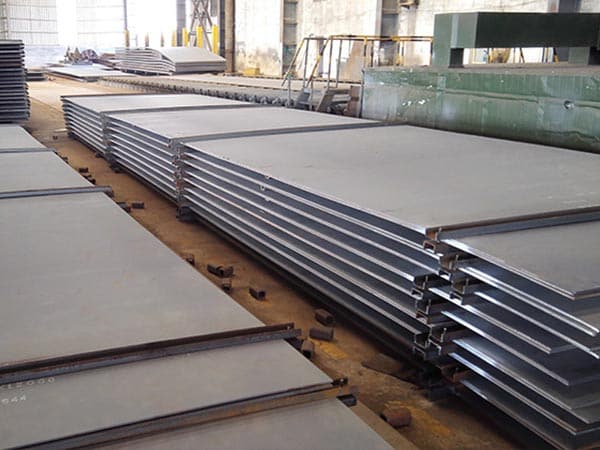

S700MC cold rolled coil with low and intermediate tensile strength

BEBON cpompany practice new development concepts, expand in an all-round way, deepen reform and innovation, speed up transformation and upgrading, become stronger, better and bigger, accelerate the implementation of BEBON Steel's S700MC cold rolled c

BEBON cpompany practice new development concepts, expand in an all-round way, deepen reform and innovation, speed up transformation and upgrading, become stronger, better and bigger, accelerate the implementation of BEBON Steel's S700MC cold rolled coil industrial planning, and realize the revitalization and development of enterprises.Fully implement the corporate S700MC cold rolled coil market dominant position, comprehensively promote contractual management, and promote the transition from "internal production" to "market operation”.

It is not the thicker the steel plate is, the better. The larger steel plate thickness means higher price and purchase cost, and it is also not inconvenient for transportation. Besides, the thickness of S700MC cold rolled coil, steel plate has relation to the safety, so the thickness of steel plate is not determined at random, and the size data of steel plate should be strictly planned according to the requirements of drawings. Therefore, it is necessary to select the appropriate steel plate material and specification according to the use.

The bridge steel plate is mainly used for erecting railway bridges, highway bridges, sea crossing bridges, etc. The bridge steel plate is required to have high strength and toughness, bear the load and impact of rolling stock, and have good fatigue resistance, certain low temperature toughness and atmospheric corrosion resistance. The bridge steel plate S700MC cold rolled coil should also have good welding performance and low notch sensitivity. If you want to have a more comprehensive and detailed understanding of bridge steel plate, welcome to visit our official website for consultation.

During cladding welding of hardfacing wear-resistant steel plate, S700MC cold rolled coil, preheating and slow cooling should not be adopted. Sometimes, forced cooling measures are even taken to reduce the residence time of weld in the temperature range of 400-850℃ to prevent local chromium deficiency in austenite grain boundary and σ brittle phase in the plate, resulting in 475℃ brittleness, so as to ensure that the weld metal has good mechanical properties and intergranular corrosion resistance.

S700MC cold rolled coil, ASTM A131 shipbuilding steel has different grade levels. The ordinary strength shipbuilding steel grades are grade A/B/D/E. Their min. yield strength is 235 Mpa, and tensile strength is 400-520 Mpa. The higher strength shipbuilding steel grades are grade AH32/DH32/EH32/FH32, AH36/DH36/EH36/FH36 AH40/DH40/EH40/FH40. The min. yield strength of AH32/DH32/EH32/FH32 steel is 315 Mpa, and tensile strength is 440-590 Mpa. The min. yield strength of AH36/DH36/EH36/FH36 steel is 355 Mpa, and tensile strength is 490-620 Mpa. The min. yield strength of AH40/DH40/EH40/FH40 steel is 390 Mpa, and tensile strength is 510-650 Mpa.

If you have steel demands in the near future, please send us inquiry in advance, as we have regular steel production plan and can arrange you a reasonable prodction time. Other than fresh production, we also have huge S700MC cold rolled coil stocks for the most widely used steel materials. So that the customers need not wait too long to get their required steel. Welcome to contact us and consult steel price, our sales person will give you professional answers and suggestions.

If customers have any difficult problems during use of the steel materials, they can contact the company's after-sales service department to feedback the existing problems. The after-sales department will reply as soon as possible to ensure that each customer has a good after-sales experience. Under special circumstances, the after-sales service department will start the problem-solving process, and the engineers in charge of the area will quickly follow up to solve the problem.

Leave a message