What is the difference between carbon steel Q235B and BS700MC heat treatment

BBN steel company was founded in 2000, starting the international business in 2010 and successfully being approved and certified by ISO9001:2008. After ten years development, BBN steel has become the large-scale comprehensive enterprise group, combining s

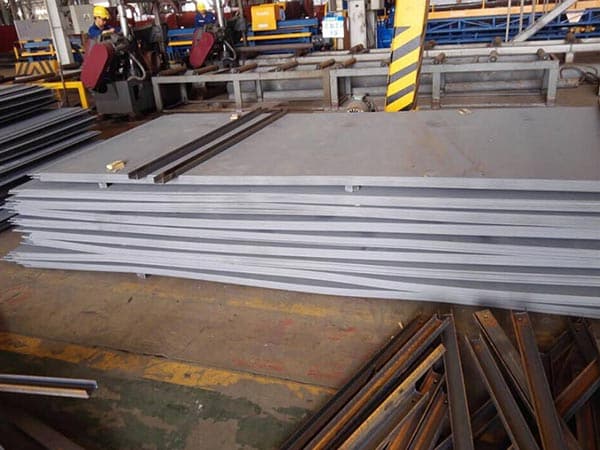

BBN steel company was founded in 2000, starting the international business in 2010 and successfully being approved and certified by ISO9001:2008. After ten years development, BBN steel has become the large-scale comprehensive enterprise group, combining steel trading, BS700MC heat treatment plate processing, and steel distribution, also have large warehouse and processional representatives both inTianJin, Zhengzhou and Beijing city.

At present, China's wear-resistant steel plate grades are divided into six levels, namely NM300, NM360, NM400, NM450, NM500, NM550 and NM600. The wear-resistant steel BS700MC heat treatment grade adopts the combination of Chinese NM of wear resistance meaning and Brinell hardness (HB) value. For example: NM500, NM is the first universal parent of Chinese "wear resistance", "500" is Brinell hardness value. NM series wear-resistant steel has good wear resistance, which greatly reduces the loss and use cost.

Boiler steel refers to the special steel used to manufacture pressure components of steam boilers, such as steam drums. The boiler steel mainly means boiler steel plates and seamless boiler steel pipes. Boiler components not only bear pressure loads but are also heated by direct fire, so the requirements on the chemical composition and mechanical properties of boiler steel, BS700MC heat treatment are strict. In the chemical composition of boiler steel, BS700MC heat treatment, sulfur and phosphorus are strictly controlled. Tensile strength, yield point, elongation, impact energy value and 180 ° cold bending are required to be tested in boiler steel mechanical properties. In addition, strain aging impact test is also required for boiler steel. The quality control of boiler steel is slightly higher than that of pressure vessel steel.

AR400 wear resistant steel is a special structural steel with high wear resistance. Generally speaking, the higher the hardness, the higher the wear resistance of the steel, BS700MC heat treatment. The average hardness of AR400 wear-resistant special structural steel is 400HB. After quenching, AR400 wear resistant steel has good martensite bainite microstructure. The addition of Molybdenum (Mo), Nickel (Ni) and Boron (B) alloys ensures uniform texture in the whole thickness direction of AR400 wear resistant steel.

ST37-2 is a kind of low carbon steel with carbon content of 0.20%, similar to S235JR or Q235 BS700MC heat treatment. It's not as strong as common ASTM A36, but it is also widely applied by everyday uses and structural applications where high strength is not so important. Equal ST37-2 angle steel size: BS700MC heat treatment Size: 20 × 20 mm to 200 × 200 mm. Thickness: 3 - 35 mm. Length: 6 m, 9 m or as required. Unequal ST37-2 angle steel size: BS700MC heat treatment Size: 30 × 20 mm to 250 × 90 mm. Thickness: 3 to 10 mm. Length: 6 m, 9 m, 12 m or per your request.

Our company has been established for 20 years and has accumulated rich experience in steel products. At the same time, it is often exported to Southeast Asia, Africa, South America and other countries. So you can rest assured that our BS700MC heat treatment products and our prices are very favorable. Because we have our own factory, there is no other cost, we can also carry out machining and so on.

The results of adopting two-level BS700MC heat treatment service system and implementing standardized management are mainly reflected in the formation of vigorous work style such as quick response and quick action. Our company's customer service center stipulates that employees must be accurate and quick in technical support and BS700MC heat treatment after-sales service. Through the formation of this fast, agile, vigorous style, to provide users with satisfactory service.

Leave a message