How to remove rust of BS700MC cold forming steel

Since its establishment, the company has always adhered to the enterprise spirit of "solid feet and lofty ideals, dare to create and take responsibility, and dedicate to work". After years of careful management, the company has achieved the doub

Since its establishment, the company has always adhered to the enterprise spirit of "solid feet and lofty ideals, dare to create and take responsibility, and dedicate to work". After years of careful management, the company has achieved the double improvement of BS700MC cold forming steel capital strength and scale expansion, gained wide recognition and general praise from all walks of life, further realized specialized and large-scale operation and optimized allocation of resources, and effectively improved the BS700MC cold forming steel overall strength, competitiveness and anti risk ability of the company.

20Mn2 steel is used to manufacture carburized parts with low requirements on the surface and core, and with a cross-sectional diameter of less than 50mm, such as carburized pinions, small shafts, and low-demand pistons instead of 20Cr steel in the manufacture of automobiles, tractors and machine tools Pins, cross pin heads, diesel engine sleeves, valve jacks, gearbox levers, steel sleeves, etc. In addition, this kind of steel can also be used to make riveting weldments, screws, nuts, etc. under hot rolling and normalizing conditions.

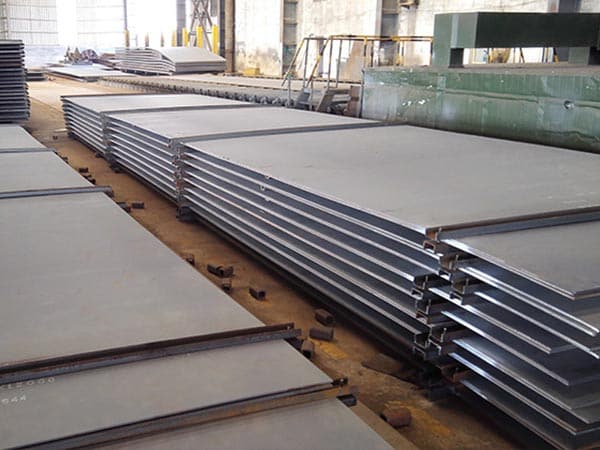

Our company produces ordinary carbon steel BS700MC cold forming steel with high strength and good plasticity and toughness. Due to the effect of alloy elements, its strength is 25% - 50% higher than that of ordinary carbon steel, its elongation is 15% - 23%, and its impact toughness at room temperature is higher than 60j / cm 2. We have a BS700MC cold forming steel production line specializing in the production of ordinary carbon steel plate, and strictly control its quality.

The microstructure of the quenched and tempered alloy steel, BS700MC cold forming steel after conventional heat treatment is tempered sorbite. For parts with wear-resistant surface (such as gears and spindles), induction heating surface quenching and low-temperature tempering are carried out, and the surface structure is tempered martensite. The surface hardness can reach 55HRC-58HRC. After quenching and tempering, the yield strength of quenched and tempered alloy steel is about 800MPa, the impact toughness is 800kJ / m2, and the core hardness is 22HRC - 25HRC. If the cross-section size is large but not quenched, the properties will be significantly reduced.

BS700MC cold forming steel, Q460D quenched and tempered steel plate spot specification: 6*2000*8500, 6*2000*10800, 45*1550*4900, 16*2000*9700, 14*1950*7030, 22.23*2181*12200, 28*2010*7300, 23.83*2179*5000, 19*2500*6000, 23.83*2179*5000, 28.58*2171*12300, 28.5*2340*12150, 28.58*2171*11500, 28.58*2171*10800, 22.23*2150*12200, 28.5*2000*12150, 28.58*2172*11500, 28.58*2172*10800, 28.58*2172*12100, 25.4*2298*13000 (mm).

our company is a professional ASTM A573 Grade 70/A573 Gr.70 carbon manganese silicon steel plates steel exporter and a steel Stockist in china. We keep more than BS700MC cold forming steel 1000 tons ASTM A573 Grade 70/A573 Gr.70 carbon manganese silicon steel plates steel in stock every month.

Provide special product requirements to meet the personalized needs of customers. The BS700MC cold forming steel company arranges production and shipment strictly according to the contract, and guarantees to supply goods according to the time agreed in the contract. Provide professional consultation: we guarantee to answer any professional and BS700MC cold forming steel technical questions raised by users within 1 hour; provide detailed information.

Leave a message