What are the operation principles to be followed in the S500MC steel for car shell cutting process

The company is a leading steel production and exporting group in steel materials with advanced production technology, metal-cutting skill, and steel structures engineering projects. We can supply carbon steel plate and sheet, alloy steel plates and struct

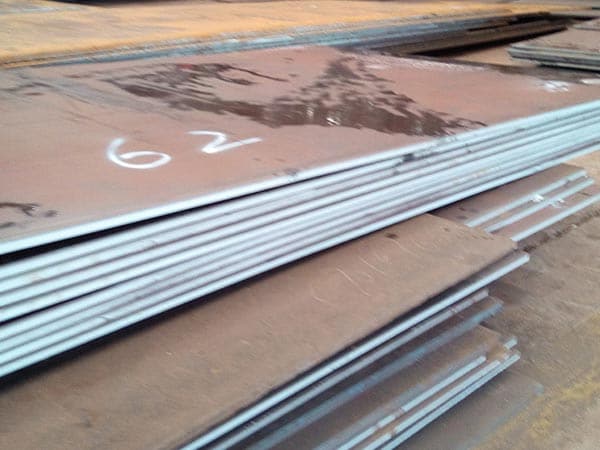

The company is a leading steel production and exporting group in steel materials with advanced production technology, metal-cutting skill, and steel structures engineering projects. We can supply carbon steel plate and sheet, alloy steel plates and structural S500MC steel for car shell steel plates. These hot rolled steel plates are sturdy plates having high quality. Their imperviousness to effect and scrapped area, weld capacity, and workability make them a worthy product in a variety of industries.

S500MC steel for car shell product is a low-alloy high-strength steel that adds a small amount of alloying elements to general steel to make it have corrosion resistance in the atmosphere. Weathering steel has 2-8 times the atmospheric corrosion resistance of ordinary carbon steel, and the longer the service time, the better the corrosion resistance. In addition to excellent weather resistance, weathering steel also has excellent mechanical and welding functions.

Just as S500MC steel for car shell, the boiler steel plate also has strict control of chemical composition for the material, especially harmful elements such as phosphorus and sulfur, and residual elements such as chromium, nickel, and copper; during smelting, good deoxidation and removal of non-metallic inclusions should be carried out to ensure good quality, plasticity and toughness. The organizational structure requires uniformity, and the grain size is controlled within a certain range; there are also strict requirements for surface quality and internal defects. In addition, the boiler steel plate mechanical properties at room temperature and high temperature must be guaranteed.

The strength level of traditional spring steel is difficult to meet the requirements of modern industrial development. As we all know, the mechanical properties of S500MC steel for car shell, spring steel depend on the heat treatment process under the premise of material quality assurance, and the heat treatment process should also be determined according to the material itself. An important way to increase the strength of spring steel is to give full play to the role of alloying elements to achieve the best alloying effect.

Alloy steel product S500MC steel for car shell size and stock (mm): 25*2200*9250, 25*2200*9200, 30*2200*10450, 35*2200*11050, 35*2000*11400, 75*2200*6100,,35*2200*9100, 50*2200*10000, 75*2200*6000, 35*2200*9300, 43*2100*12000, 70*2200*6500, 60*2200*10000, 60*2200*7450, 40*2200*11050, 43*2100*12000, 65*2200*6800, 90*2200*10000, 70*2200*10000, 110*2200*10000, 130*2200*10000, 150*2200*10000.

We have replenish steel materials stocks, now there are huge stocks of s355jr, A36, S500MC steel for car shell A572 Gr 50, 16Mo3, A516 Gr 70, ABS grade A, AH32, AH36, EH36, SPA-H, SG295,SM700C etc steel materials. We can arrange delivery for those stock steel products within short time. Meanwhile, we also provide further processing for the S500MC steel for car shell steel materials, such as cutting, drilling, bending, welding, etc. Please do not hesitate to contact us if you have any steel demands.

Respect customers and treat each other sincerely. Customers are always right. Always remember that the user is the God of the enterprise, respect the customer, and accept the customer's opinion modestly is the guarantee of the long-term development of the enterprise. Adhere to this concept, so that the service and the product are the same, long-term.

Leave a message