How to protect B750L plate zero cut from crack

The company specializes in the research and development, production and sales of B750L plate zero cut seamless pipes, longitudinally welded pipes, large-diameter welded pipes, API 5L welded pipes, spiral welded pipes, and large-diameter thick-walled strai

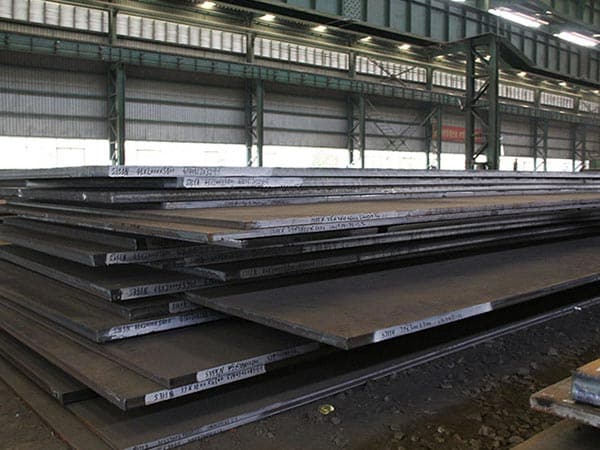

The company specializes in the research and development, production and sales of B750L plate zero cut seamless pipes, longitudinally welded pipes, large-diameter welded pipes, API 5L welded pipes, spiral welded pipes, and large-diameter thick-walled straight seam steel pipes. The company has B750L plate zero cut five production lines in three major production workshops: large-diameter longitudinally welded pipe production workshop,B750L plate zero cut rolled steel pipe production workshop, and thermally expanded steel pipe production workshop, with an annual production capacity of more than 100,000 tons.

ASTM A283 steel B750L plate zero cut is a carbon steel plate used for general structural purposes. This steel has low strength and medium strength. It has two steel grades (C and D). For steel coils or unheated steel plates, additional stress relief tests should be carried out. Usually, inspections, inspections, and B750L plate zero cut heat treatments should be carried out before leaving the factory after the coils are opened.

The wear resistance of the surface of the wear-resistant composite plate not only has good hardness, but also can be added with nickel alloy to improve its corrosion resistance. Generally, there are few single working conditions in the industry, and there are more or less heterogeneous factors such as wear and corrosion, high temperature, impact, etc., the chromium-nickel alloy of the wear-resistant layer of the composite steel plate, B750L plate zero cut, is welded, so its wear resistance is good, and it also has good corrosion resistance.

Rolled sheet is a very common material in industrial construction. Rolled sheet at room temperature is cold-rolled sheet, and cold-rolled sheet is the rolling of hot-rolled coils below the recrystallization temperature. The hot-rolled sheet is rolled above the recrystallization temperature. So what is the difference between B750L plate zero cut, hot rolled sheet and cold rolled sheet?

SA514 grade T asme structural steel plate element composition%C: 0.08-0.14, Si: 0.40-0.60, Mn: 1.20-1.50, P max.: 0.035, S max.: 0.010, B max.: 0.005, Mo: 0.15-0.30, V: 0.03-0.08The mechanical properties in thickness (mm) T≤65Yield strength (≥Mpa): 690Tensile strength (Mpa):760-895Elongation in ≥,%: 18

The high strength B750L plate zero cut low alloy steel, which is shorten as HSLA steel, is one of our main products. We have professional team to serve you. For any demands or questions about HSLA steel, for example, ASTM A572 grade 50 chemical composition, difference between s355jr and S355J2, mechanical properties of B750L plate zero cut ST52 steel, Q345B tensile strength, Q345D steel ASTM equivalent, HSLA steel price etc. , please do not hesitate to contact us and consult.

The company has passed the ISO9001: 2008 quality system certification, strictly implemented the ISO9001 quality management system. Besides, we have continuously improved the after-sales service network to make every effort to provide more convenient, accurate and faster services for all customers. We will supervise the production, control the quality in the factory, Inspect the cargo before shipment, Issue the test report to sales department. From the steel prodcution to steel delivery, we always focus the whole process.

Leave a message