How to correct the tortuosity of S460MC Steel for automotive inner panels

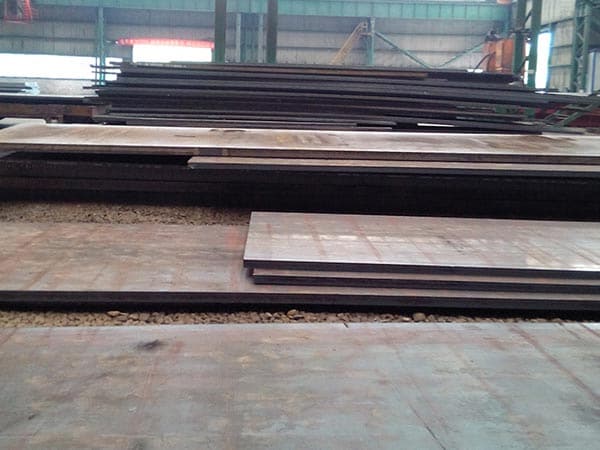

The company is a large S460MC Steel for automotive inner panels steel supplier and exporter specializing in steel coil, steel plate, steel tube and section steel. The company has always put service and quality first, offered reasonable price, taken small

The company is a large S460MC Steel for automotive inner panels steel supplier and exporter specializing in steel coil, steel plate, steel tube and section steel. The company has always put service and quality first, offered reasonable price, taken small profits and quick turnover as the principle, honest and trustworthy as the purpose. The success of the company is not only the hard work and wisdom of all the employees of the company, but also the deep love of our customers. We will continue to achieve new leaps and create greater brilliance of the S460MC Steel for automotive inner panels enterprise, and make our own contribution to the development of the world economy.

The production process of hot-rolled steel plate and cold-rolled steel plate is different. Hot rolled steel plate is rolled at high temperature, and cold rolled steel plate is rolled at normal temperature. Generally speaking, cold rolled steel plate has better strength and hot rolled steel plate has better ductility. The thickness of S460MC Steel for automotive inner panels cold rolling is generally smaller, and that of hot rolling can be larger. The surface quality, appearance and dimension accuracy of cold rolled steel plate are better than that of hot rolled steel plate.

Grade E, Grade EH32, Grade EH36 series shipbuilding steel products have good comprehensive mechanical properties, welding performance, process performance. Our shipbuilding steel plate and S460MC Steel for automotive inner panels steel sections are suitable for manufacturing structural parts such as ship hull structures, docks, oil production platforms, marine transmission pipelines, coastal power plants, wharf facilities in ocean, coastal and inland navigation areas.

The strengthening mechanisms in metals mainly include solid solution strengthening, dislocation strengthening, fine grain strengthening, and second phase (precipitation and dispersion) strengthening. Alloying elements have the most significant strengthening effect on steel in the quenched and tempered state, because it makes full use of all four strengthening mechanisms. Martensite is formed during quenching, and carbides are precipitated during tempering, resulting in a strong second phase strengthening and greatly improving toughness. Therefore, obtaining martensite and tempering it is the most economical and effective comprehensive strengthening method for S460MC Steel for automotive inner panels.

Chemical composition of Q390C steel plate: C ≤ 0.20, Si ≤ 0.50, Mn ≤ 1.7, P ≤ 0.030, S ≤ 0.030, Nb ≤ 0.07, V ≤ 0.20, Ti ≤ 0.20, Cr ≤ 0.30, Ni ≤ 0.50, Cu ≤ 0.30, N ≤ 0.015, Mo ≤ 0.10, Al ≤ 0.015. The mechanical properties of Q390C steel plate are: yield strength ≥ 390 MPa, tensile strength 470-620 MPa, elongation after fracture ≥ 18%, impact energy 34J. S460MC Steel for automotive inner panels, Q390C steel plate is used for bridges, vehicles, ships, workshops and other large structural parts, high and medium pressure Petrochemical vessels, boiler tubes, pipes, superheaters, pressure vessels, heavy machinery, etc. application.

The automobile steel coil and sheets are one of our main steel materials exported to the overseas. For any questions about automobile steel, for example, JIS G3113 SAPH440 S460MC Steel for automotive inner panels chemical & mechanical composition, S355MC material specification, S700MC material properties, QSTE 380 TM equivalent, please contact us freely. Our sales person and technician will give you professional answers. And welcome to consult us about automobile steel price.

Before delivering our hot rolled plate product we apply various tests to check the quality of carbon steel S460MC Steel for automotive inner panels plates such as- mechanical test, chemical test, hardness test, toughness test, eddy current test, impact test, micro test, flaring test, flattening test, etc. We are provided best packing for structural steel plates to avoid rust. Our after-sales service team will contact you if you have any question.

Leave a message