What is the role of welding preheating for BS700MC heat treatment

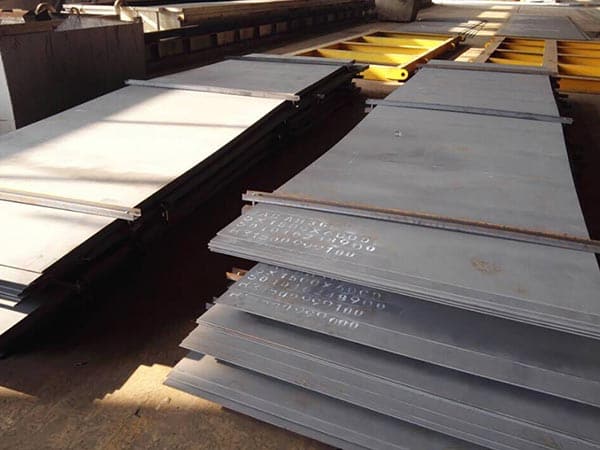

We are a popular factory, supplier and wholesaler of mild steel plates and alloy steel plates in all over the globe. We follow all standards and specifications of BS700MC heat treatment boiler steel plate, structural steel plate, shipbuilding steel plates

We are a popular factory, supplier and wholesaler of mild steel plates and alloy steel plates in all over the globe. We follow all standards and specifications of BS700MC heat treatment boiler steel plate, structural steel plate, shipbuilding steel plates and corten steel in different types. We manufacture and supply steel plates, steel section and steel structures according to customer’s demand. The company also focus on providing customers with BS700MC heat treatment high-end steels and competitive price.

The size, shape, weight and allowable deviation of Q390D, Q390D-Z35 steel plate should comply with the provisions of GB/ T709-2016. The maximum thickness of the steel plate is 135mm. When the BS700MC heat treatment, Q390D steel, Q390D-Z35 plate thickness is less than 100 mm, the required performance level in the thickness direction is z25; when the thickness is ≥ 100 mm, the required performance level in the thickness direction is Z35, which shall specifically comply with the provisions of GB/T5313-2010.

The yield point of the steel structure determines the stress that the structure can withstand without permanent deformation. The minimum yield point of typical carbon structural steel is 235MPa. The minimum yield point of typical low-alloy high-strength steel is 345MPa. Therefore, according to the proportional relationship of its yield point, the use of low-alloy high-strength steel allows the stress to be 1.4 times higher than that of carbon structural steel. Compared with BS700MC heat treatment, carbon structural steel, the use of low-alloy high-strength steel can reduce the size of structural parts and reduce weight.

The work performance of BS700MC heat treatment etc. steel material is mainly depended on its chemical composition, mechanical properties etc. parameters. The higher strength the steel has, the less quantity steel is needed to achieve same strong effect of the steel structure. However, the steel strength varies with the thickness. So please take steel thickness into consideration when evaluating the steel strength. For a certain steel, its strength also has something to do with the steel shape. For example, for a same steel grade, the steel strength is different for steel plates and pipes.

Difference between Q235A steel and Q235B steel plates: in the national standard GB700, the difference between BS700MC heat treatment, Q235A steel and Q235B steel plates is mainly in the carbon content. In addition, Q235A steel plate does not do impact test, while Q235B Q235B steel plates need normal temperature impact test, V-notch. Relatively speaking, the mechanical properties of Q235B steel plates are better than that of Q235A steel plate.

The company always adheres to the quality policy of "Quality First, Continuous Improvement, Customer Satisfaction" and the business philosophy of "Continuous Progress, Pursuing Excellence", as always, we look forward to cooperating with you to create a new situation for common development.Steel products BS700MC heat treatment price concessions, rich industry experience, complete varieties.

From the order to the delivery, there are three quality inspections to ensure that the qualified rate of finished products is more than 100%. We promise that every order will be tracked in a timely manner to ensure that customers can receive goods safely and constantly listen to their opinions and suggestions, reflect on our own problems, and let customers feel at ease. We have a large warehouse in Shanghai and Tianjin, which can provide customers with sufficient sources of supply.

Leave a message