cold forming S355MC high-strength steel ASTM equivalent steel grade

Since it was established in 2000. Based on the domestic rich cold forming S355MC high-strength steel product resources and the great steel demand of the international market, our cold forming S355MC high-strength steel service has already spread many coun

Since it was established in 2000. Based on the domestic rich cold forming S355MC high-strength steel product resources and the great steel demand of the international market, our cold forming S355MC high-strength steel service has already spread many countries in Europe , America, Southeast Asia, Middle East, South America, Africa, etc, and we have won an outstanding reputation for its professional exporting steel products

cold forming S355MC high-strength steel, 45# steel is carbon steel, belonging to high strength medium carbon quenched and tempered steel, with carbon content of 0.45%, so it is called 45# steel. 45# steel does not contain specially included alloy elements. cold forming S355MC high-strength steel, 45# steel is one of the most widely used high-quality structural steel. 45# steel is suitable for manufacturing high strength moving parts, such as air compressor, piston of pump, impeller of steam turbine, rolling shaft, connecting rod, worm, rack, gear and pin in heavy and general machinery.

20G steel is boiler steel, which is similar to No. 20 carbon steel. The difference is that 20G steel has higher and stricter inspection standards than cold forming S355MC high-strength steel, No. 20 carbon steel for harmful impurities and internal defects. That is to say, 20G steel is specially produced for boiler pressure vessels. It is special purpose "No. 20 carbon steel". The use of 20G steel to make boilers is not because it is more resistant to burning than other steels such as cold forming S355MC high-strength steel, but because of its strength, toughness, ductility, weldability, temperature influence, fatigue fracture, price and cost, etc. 20G steel is most suitable for use in medium and low pressure boilers.

In order to prevent the deformation of cold forming S355MC high-strength steel, wear-resistant composite plate during preheating, the steel plate with good quality should be selected first. The steel plate with serious carbide segregation should be reasonably cast and heat treated by quenching and tempering. For the large and non cast wear-resistant composite plate, the solution double refining heat treatment can be carried out. At the same time, the heating temperature should be reasonably selected and the heating speed should be controlled.

20 # material is a high-quality low-carbon carbon steel, cold-extruded, carburized and hardened steel. cold forming S355MC high-strength steel, 20 # material has low strength, good toughness, plasticity and good weldability. Chemical composition of 20 # round steel bar: C: 0.17 ~ 0.23, Si: 0.17 ~ 0.37, Mn: 0.35 ~ 0.65, S: ≤0.035, P: ≤0.035, Cr: ≤0.25, Ni: ≤0.30, Cu: ≤0.25. 20# carbon steel mechanical properties: Shear strength 275 ~ 392MPa, Tensile strength is 253 ~ 500MPa, elongation min. 25%.

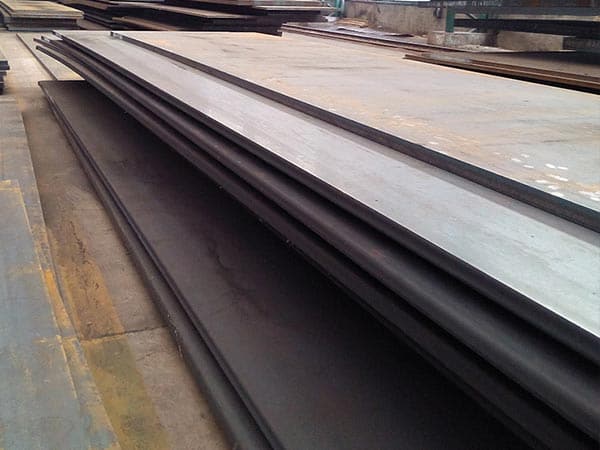

Hot rolled plates are known for their superior mechanical properties over commodity grades of merchant bar. The hot rolled cold forming S355MC high-strength steel plates products are made to specific chemistry and mechanical properties ranges, allowing them to be used in engineered applications. Resulting shafts, axles, and gears can be used in the automotive cold forming S355MC high-strength steel industry and agriculture equipment. A36 mild steel has good strength, formability, and excellent welding properties. We also can supply welding, fabricating, and bending service.

We should help solve the customer's problems in time, not just verbally, without solving the problems or shirking the responsibility. Improving after-sales efficiency can make customers feel respect. We should take their problems seriously and show sincerity. It can also give customers a good impression and reduce the negative impact.

Leave a message