What is the EN10111 DD1 steel for cold forming automobile size range?

The impression of most customers who have cooperated with us on the company is being professional and responsible. That mainly owe to our united and considerate team members. For example, the professional technician, the responsible QC inspector, the expe

The impression of most customers who have cooperated with us on the company is being professional and responsible. That mainly owe to our united and considerate team members. For example, the professional technician, the responsible QC inspector, the experienced sales person, the rigorous document maker, the patient after-sales, etc. Their selfless devotion bring the customer good experience, and bring the company good reputation.

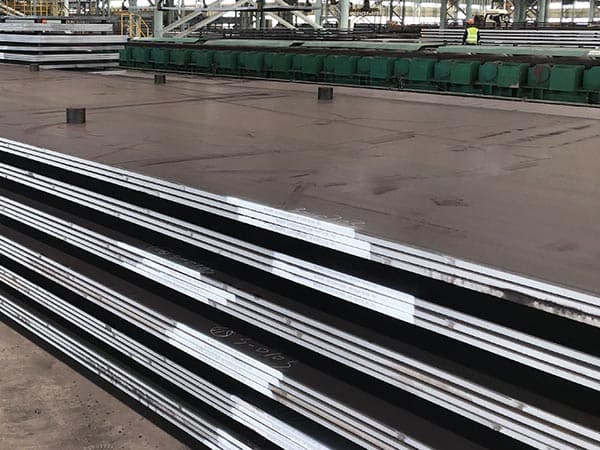

High quality pipeline steel plate is the key material for ERW line pipe, LSAW line pipe and EN10111 DD1 steel for cold forming automobile SSAW line pipe. It is widely used in oil, natural gas and water transportation pipeline construction, and can be used for manufacturing pressure fluid transportation construction.

Composition of low alloy steel plate: Low carbon: due to the high requirements for toughness, weldability and cold formability of low alloy steel plate, the carbon content is not more than 0.20%; manganese is added; the auxiliary elements such as niobium, titanium or vanadium are added; a small amount of niobium, titanium or vanadium forms fine carbide or carbonitride in the steel, which is conducive to obtaining fine ferrite grains and improving the strength and toughness of low alloy steel plate; in addition, The corrosion resistance of EN10111 DD1 steel for cold forming automobile, low alloy steel plate can be improved by adding a small amount of copper (< 0.4%) and phosphorus (about 0.1%).

Blast furnace ironmaking is a traditional ironmaking method based on coke energy. It cooperates with converter steelmaking and is the main method of producing EN10111 DD1 steel for cold forming automobile steel at present. This dominance of blast furnace ironmaking is not expected to change for quite a long time. The essence of blast furnace ironmaking is the reduction of iron. Besides, coke is used as fuel and reducing agent. At high temperatures, iron ore or iron-containing raw materials are reduced from an oxide or mineral state to liquid pig iron.

We have a professional after-sales service team, the company has developed a clear service process and service standards, after-sales service team members strictly perform after-sales procedures, comply with service standards. The most important thing is that we have set up the correct concept of after-sales service, "customer first, sincere service for users".

We provide customers with demand support and better serve them. We are committed to actively meet the needs of customers, always keep in touch with them in a timely manner, leave a good impression for customers, and make customers satisfied through our unremitting efforts. Customer satisfaction is our most basic vision, striving to become the best steel product service provider in the world

Leave a message