Ukraine high yield strength alloy en 10149-2 s700mc top five manufacturers

Compared with 12CrMoV steel, , 12Cr1MoVR pressure vessel steel has higher oxidation resistance and heat strength. The creep limit of this steel is very close to the endurance strength value, and it has high plasticity under the condition of long-term stre

Compared with 12CrMoV steel, , 12Cr1MoVR pressure vessel steel has higher oxidation resistance and heat strength. The creep limit of this steel is very close to the endurance strength value, and it has high plasticity under the condition of long-term stretching; the steel has good manufacturability and weldability, but it needs to be preheated to 300 ° C before welding, and the stress needs to be removed after welding deal with.

SA516Gr.70 steel chemical composition (%):C≤0.30, Mn: 0.79-1.30, P≤0.035, S: ≤0.035, Si: 0.13-0.45. ASME SA516Gr.70 material is a carbon steel grade for medium and low temperature pressure vessels. In order to meet the different requirements of users and facilitate production management, the S and P requirements of steel grades are divided into three levels of Ⅰ, Ⅱ and Ⅲ. , SA516Gr.70 pressure vessel steel is used to improve the notch toughness of welding steel plates for pressure vessels.

Adhere to the spirit of quality first and user foremost, carry out maintenance and other work according to the requirements of the buyer's contract, and ensure that the engineering project and product after-sales play their application effectiveness. Our company guarantees to carry out self inspection and self supervision according to the quality management policy proposed by our company, and deliver a high-grade, perfect and excellent system engineering to users.

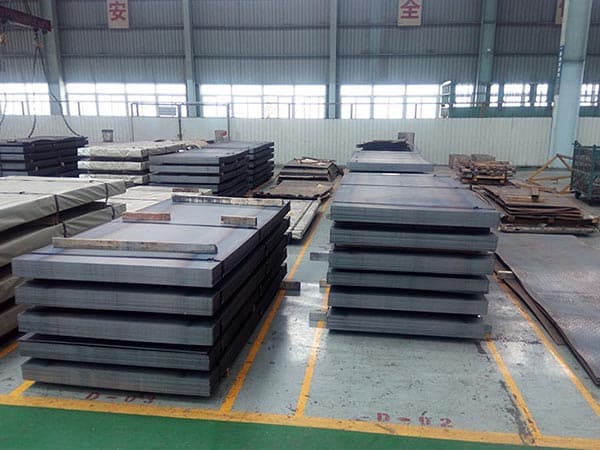

The X80M pipeline steel customized by the company for customers will be supplied to a construction machinery manufacturing enterprise for making core components of rotary drilling rigs. Based on the original production process of high-end pipeline steel, the company formulated and optimized the process plan and production operation plan, strictly controlled the content of harmful elements in the production, optimized the rolling parameters and cooling mode, and ensured that all performance indexes of customized X80M high yield strength alloy EN 10149-2 S700MC pipeline steel met the requirements of customers.

Leave a message