The S 500 MC yield strength from BBN

The company has five major departments: steel plate production department (including quality inspection team), sales department, market development department, after-sales and logistics department, and finance department. The backbone of steel business fr

The company has five major departments: steel plate production department (including quality inspection team), sales department, market development department, after-sales and logistics department, and finance department. The backbone of steel business from all over the country, with the chairman as the core, integrates self-confidence, independence, passion and responsibility, and strives for excellence! All people share the same belief: "Being a refined steel product line rewards customers, strengthen the steel industry, and realize the corporate dream!

We have new significant S 500 MC projects in Nigeria. It is about crude oil storage tanks. With the development of our steel materials business in the Africa those years, Nigeria has been an important market to us. And we have many S 500 MC famous projects in local and also participated in a lot of governmental projects. This crude oil storage tanks project is a very big engineering, and lasts for years. This is the only initial stage. We are under negotiation about following installation and further demands etc. matters.

The alloy layer of clad wear-resistant plate is mainly made of chromium carbide, and it is also equipped with molybdenum, niobium, titanium, boron and other components. The formation of multi-element carbides also has strong stability at high temperatures and can still be maintained below 500 °. High hardness and good oxidation resistance. The new clad wear-resistant plate S 500 MChas multiple performances of wear resistance, corrosion resistance, temperature resistance and impact resistance.

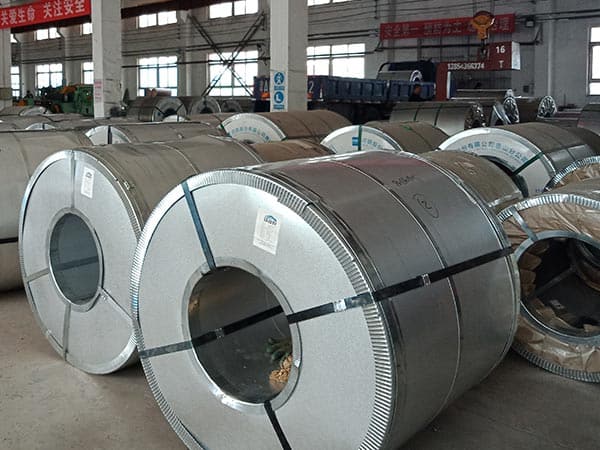

In the process of S 500 MC steel transportation, enterprises often use railway transportation, highway transportation, water transportation and other ways to transport. According to the cargo owner's requirements on the timeliness of the goods and the different transportation routes, our company will choose S 500 MC different modes of transportation. According to the specific needs of customers, or specify the mode of transportation.

Non-destructive flaw detection of steel plates is a test method for inspecting the S 500 MC surface and internal quality of the inspected parts without damaging the working state of the workpiece or raw materials. Commonly used S 500 MC steel plate flaw detection methods include: X-ray flaw detection, ultrasonic flaw detection, magnetic particle flaw detection, penetration flaw detection, eddy current flaw detection, gamma-ray flaw detection, fluorescent flaw detection, color flaw detection and other methods. Physical flaw detection is non-destructive flaw detection without any chemical changes.

The company has passed the ISO9001: 2008 quality system certification, strictly implemented the ISO9001 quality management system. Besides, we have continuously improved the after-sales service network to make every effort to provide more convenient, accurate and faster services for all customers. We will supervise the production, control the quality in the factory, Inspect the cargo before shipment, Issue the test report to sales department. From the steel prodcution to steel delivery, we always focus the whole process.

Leave a message