BBN supply S315MC cold forming autobobile steel tensile strength

Our company attaches great importance to technical support and after-sales service, and has established a customer service center to provide unified technical support and service for S315MC cold forming autobobile steel various engineering projects. Custo

Our company attaches great importance to technical support and after-sales service, and has established a customer service center to provide unified technical support and service for S315MC cold forming autobobile steel various engineering projects. Customer service center has a strong technical force of technical service team, composed of a customer service center manager, several S315MC cold forming autobobile steel after-sales service personnel, responsible for unified acceptance and processing of local after-sales service needs.

The alloy layer of clad wear-resistant plate is mainly made of chromium carbide, and it is also equipped with molybdenum, niobium, titanium, boron and other components. The formation of multi-element carbides also has strong stability at high temperatures and can still be maintained below 500 °. High hardness and good oxidation resistance. The new clad wear-resistant plate S315MC cold forming autobobile steelhas multiple performances of wear resistance, corrosion resistance, temperature resistance and impact resistance.

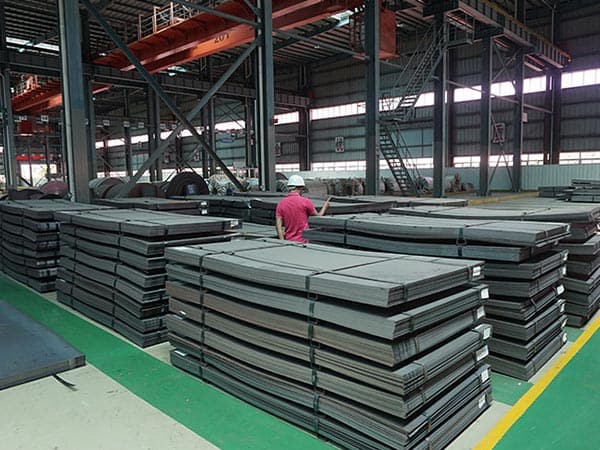

We have strong strength of steel plate production, high-quality products, and low prices. Guarantee to thank the new and old customers for their trust with good products, excellent quality, low price and perfect service. The company provides customers with professional "one-stop" logistics services: warehousing, loading and unloading, and transporting. The perfect logistics management, facilities, network and guarantee system guarantee customers' worry-free delivery.

Non-destructive flaw detection of steel plates is a test method for inspecting the S315MC cold forming autobobile steel surface and internal quality of the inspected parts without damaging the working state of the workpiece or raw materials. Commonly used S315MC cold forming autobobile steel steel plate flaw detection methods include: X-ray flaw detection, ultrasonic flaw detection, magnetic particle flaw detection, penetration flaw detection, eddy current flaw detection, gamma-ray flaw detection, fluorescent flaw detection, color flaw detection and other methods. Physical flaw detection is non-destructive flaw detection without any chemical changes.

Leave a message