#4 Finish s355mc vs s355j2 for auto frame Stockist

The company adheres to the "variety, quality and efficiency" road. We have established a technology center, a brand cultivation management system and a quality control system. Now the company has formed an independent innovation system integrati

The company adheres to the "variety, quality and efficiency" road. We have established a technology center, a brand cultivation management system and a quality control system. Now the company has formed an independent innovation system integrating S355MC vs s355j2 for auto frame production, learning, research and marketing. Our company has passed ISO9001 quality management system certification and ISO10012 measurement management system certification.

ArcelorMittal USA said s355mc vs s355j2 for auto frame it was planning to work with the United Steelworkers union "to minimize the impact on its employees. The company will continue to communicate with its customers to understand the market impact of the outbreak of covid-19, which may require additional capacity optimization to maintain a balance between supply and demand.

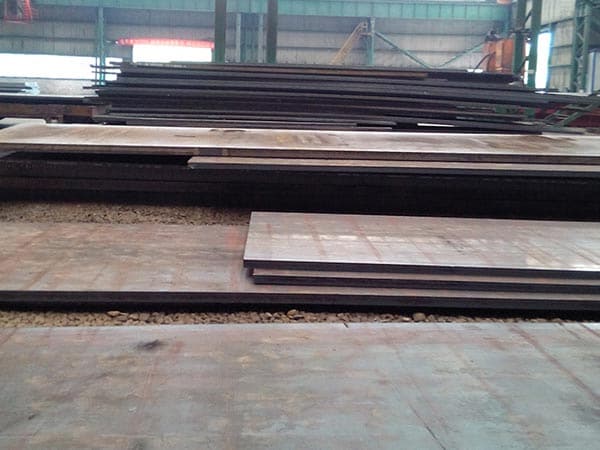

The company specializes in steel plate cutting, steel plate processing and wide thick plate, hot rolling coil. The company possesses advanced CNC steel plate cutting processing equipment, first-class technical personnel, supporting marketing and after-sales service system. Steel plate cutting parts are mainly used in mechanical manufacturing, shipbuilding, steel structure and mold processing industries, and we can provide s355mc vs s355j2 for auto frame, finished products and semi-finished products processing according to the needs of users.

The main reference for structural design of steel structure engineering is the static and dynamic characteristics of the steel used under various actions, such as elasticity, plasticity, strength, toughness, fatigue and other mechanical properties. Therefore, the s355mc vs s355j2 for auto frame and so on steel used in the construction of steel structure engineering will limit its strength, plasticity, impact toughness and weldability. Steel structure engineering requires high tensile strength and yield point of steel. High yield point can reduce the cross-section of the component, so as to reduce the weight, save steel and reduce the cost. High tensile strength can increase the safety of the structure.

As a leading international steel supplier, we have two warehouses, close to Tianjin port and Shanghai port. This superior geographical location effectively saves the domestic transportation cost and greatly improves our service level. At the same time, it also shortens our delivery time and provides more convenience for customers.

Leave a message