4-1/4 inch S315MC steel for boom hot rolled plate

Our company's technical department is the core department of the whole company. There are a group of very professional technical personnel. They provide some architectural drawings according to the ideas of customers, and they are responsible for how

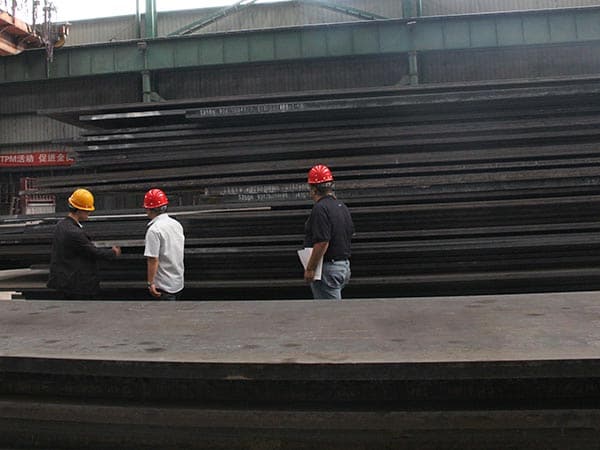

Our company's technical department is the core department of the whole company. There are a group of very professional technical personnel. They provide some architectural drawings according to the ideas of customers, and they are responsible for how to select the right materials. Including the evaluation of steel products such as multi steel plate, S315MC steel for boom and steel pipe, grasp the whole production process, and strictly follow the production standards and customer quality requirements.

The common uses of S315MC steel for boom, boiler and pressure vessel steel plate are as follows. First, make boilers and pressure vessels. Boiler and pressure vessel steel plate not only has a certain strength, but also has a certain ability to withstand impact. The boiler and pressure vessel steel plate should be resistant to abrasion and high temperature. Second, the boiler and pressure vessel steel plate is used to make spherical tank, oil gas tank, liquefied gas tank and other tanks. The boiler and pressure vessel steel plate should have the characteristics of corrosion resistance and pressure resistance.

The hardness of S315MC steel for boom, wear-resistant steel plate is an important standard to measure wear resistance. The hardness of wear-resistant steel plate can be divided into microhardness and surface hardness. The microhardness of carbide in the wear-resistant layer of wear-resistant steel plate can reach over HVl700-2000, and the surface hardness can reach HRC58-62. Chromium alloy is the main wear-resistant layer of wear-resistant steel plate, and other alloy components such as manganese, molybdenum, niobium, nickel are added at the same time.

Quenching is a heat treatment process in which steel parts are heated to above the critical temperature, and after proper heat preservation, the parts are quickly cooled to room temperature in water or oil, so that martensite transformation occurs. The hardness of the quenched S315MC steel for boom increases sharply. Quenching is to prepare the organization for adjusting and improving the performance of S315MC steel for boom during tempering, while tempering determines the performance and life of the workpiece.

The company formulates clear service process and service standard. To do a good job in after-sales service, first of all, clear service process and service standards should be formulated to let employees know which procedures to perform and which service standards to abide by.

Insist on the spirit of development and indomitable entrepreneurship; the spirit of leading science and technology and striving for first-class affairs; the spirit of strict management and market development; the spirit of taking the lead in setting an example and selfless dedication; and the spirit of people-oriented and enterprise ownership.

Leave a message