steel for truck chassis assemblies welding procedures

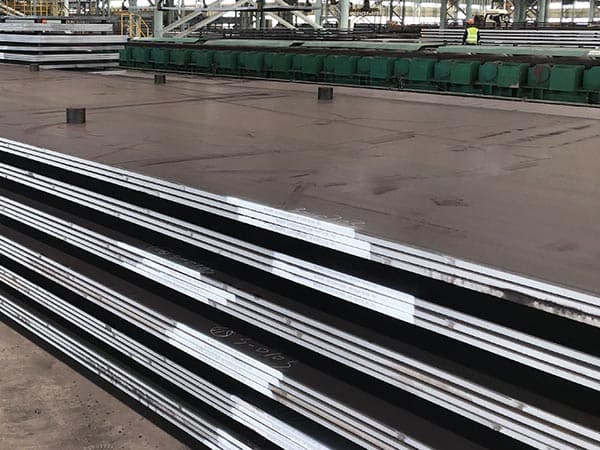

In the second step of hot rolling process, different finished mills are used to roll billets or continuous casting billets into finished steel of proper shape and size. This steel for truck chassis assemblies production process is called finished product

In the second step of hot rolling process, different finished mills are used to roll billets or continuous casting billets into finished steel of proper shape and size. This steel for truck chassis assemblies production process is called finished product production, which is generally divided into two stages of rough rolling and finish rolling. In the roughing stage, a large amount of reduction (reduction per pass) is adopted to reduce the number of passes and improve the output; after roughing, the finishing stage is entered, and the finishing is carried out with a small amount of reduction to achieve a good surface and accurate steel for truck chassis assemblies size.

Carbon steel SA516Gr70 corresponding material is SA516 Gr485 steel. SA516 Gr485 is called according to the min. tensile strength 485MPa. Our company can supply steel for truck chassis assemblies, ASME SA516Gr70 carbon steel plate and sheet with thickness ranging from 5mm to 150mm. SA516Gr70 steel plate for pressure vessels and boiler is delivered in hot rolling, controlled rolling, normalizing, while plate thickness greater than 40mm must be normalizing.

In the final analysis, the market competition is the competition for customers. Whether selling products or services, the final customer satisfaction is the standard to test the success or failure of marketing work. The so-called after-sales service is to fully understand customers, study customer psychology, pay attention to after-sales details, improve work shortcomings, improve service quality, and Exchange customer brand loyalty through the whole process of quality service.

The company formulates clear service process and service standard. To do a good job in after-sales service, first of all, clear service process and service standards should be formulated to let employees know which procedures to perform and which service standards to abide by.

Our company has a comfortable office environment, covers a large area, can accommodate hundreds of people working at the same time. All kinds of green plants are placed in the company, with a healthy office environment. Our company also has gym, table tennis, leisure bar, kitchen, refrigerator, microwave oven and other equipment. Humanized construction provides comfortable office environment for employees.

The steel for truck chassis assemblies pressure vessel steel plates are our featured products. We have supplied pressure vessel steel plates to tank manufactures, boiler makers, power plants and so on customers all over the world. We have online service for you at any time, welcome to contact and learn more information about pressure vessel steel, such as steel for truck chassis assemblies ASTM A537 class 1 equivalent, 16Mo3 datasheet, Q245R material properties, q345r material specification, P355GH properties, pressure vessel steel price, etc.

Leave a message