S355MC cold forming autobobile steel coil composition for welded steel pipe

Established in 2014, Steel Safety Day was set up to reinforce awareness of the five most common causes of safety incidents and to create a safer working environment across the entire steel industry worldwide. By focusing every year on the five causes - mo

Established in 2014, Steel Safety Day was set up to reinforce awareness of the five most common causes of safety incidents and to create a safer working environment across the entire steel industry worldwide. By focusing every year on the five causes - moving machinery, working at heights, falling objects, on-site traffic and S355MC cold forming autobobile steel coil composition process safety incidents - worldsteel intends to set up a continuous improvement process and reiterate its commitment to the safety and health of the people who work in the S355MC cold forming autobobile steel coil composition industry.

After comprehensive and professional training such as customer service, the customer service team has more strict discipline in the management of customer service team to ensure that customer service personnel respond to customers with a professional attitude. A process supervision system has been set up to let each customer supervise the process of the system with us

In April 2018, our Philiphine customer purchased 1008 Tons API5 L Gr.B ERW&Q345B SMLS pipe S355MC cold forming autobobile steel coil composition for offshore oildfield resources drilling project. This is a regular demand almost two month, and we has been cooperated more than three times, totally around 2100 tons steel pipe since 2015 year.

Both steelmaking and ironmaking are carried out by oxidation-reduction reaction, but there are great differences between them in reaction objects: ironmaking is to reduce iron, while S355MC cold forming autobobile steel coil composition steelmaking is to remove excessive carbon and other impurities in pig iron, so there are relations and differences between them in actual operation. There are three main methods of S355MC cold forming autobobile steel coil composition steelmaking: converter, electric furnace and flat furnace. The converter steelmaking process is most widely used.

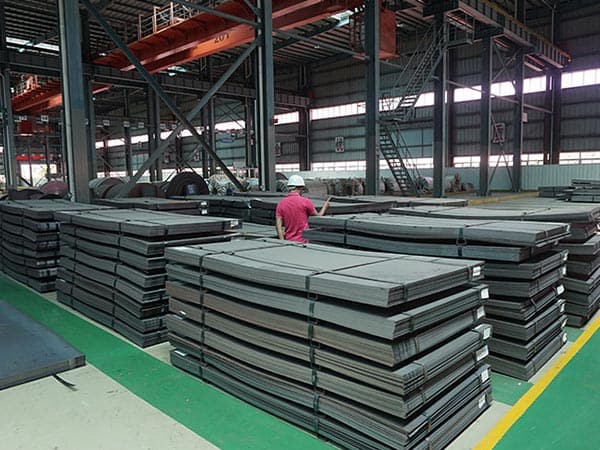

The wear-resistant layer of S355MC cold forming autobobile steel coil composition wear-resistant steel plate is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are added. The carbide in the microstructure is distributed in the form of fiber, and the direction of the fiber is perpendicular to the surface. The microhardness of carbides can reach hv1700-2000 and HRC58-62 respectively. The alloy S355MC cold forming autobobile steel coil composition carbide has strong stability at high temperature, high hardness and good oxidation resistance. It can be used normally within 500 ℃.

Our company has a comfortable office environment, covers a large area, can accommodate hundreds of people working at the same time. All kinds of green plants are placed in the company, with a healthy office environment. Our company also has gym, table tennis, leisure bar, kitchen, refrigerator, microwave oven and other equipment. Humanized construction provides comfortable office environment for employees.

Leave a message