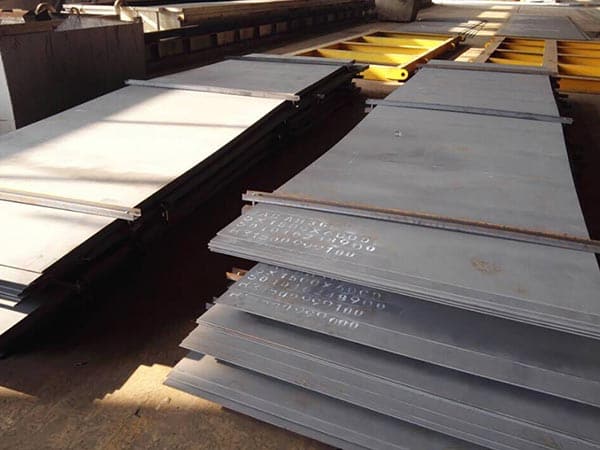

Morocco customer purchase 3700 ton B750L steel for automobile components

Our B750L steel for automobile components pipeline steel has once again helped the construction of the China-Russia East Line Natural Gas Pipeline. During 2017 - 2018, the company successively supplied more than 10,000 tons of high-grade pipeline steel ma

Our B750L steel for automobile components pipeline steel has once again helped the construction of the China-Russia East Line Natural Gas Pipeline. During 2017 - 2018, the company successively supplied more than 10,000 tons of high-grade pipeline steel materials for the northern section of the Sino-Russian Eastern Gas Pipeline project, helping the northern section of the B750L steel for automobile components project to be successfully completed. Now we reload the task and will provide API 5L X80 high-grade pipeline steel for the middle section of the China-Russia Eastern Gas Pipeline project.

BBN employees work hard and work hard in their work. In life, colleagues care about each other, like a family, and accompany each other at important moments in life. BBN Steel organizes employees to carry out tourism activities every year, so that families can be exposed to nature and relax physically and mentally. The good combination of working and rest can achieve the goal of hard work and happy life.

Tunisia cutomer purchased around 1500 tons 304L,310S stainless steel plate from us and make tanks in August, 2017. The company was skilled in the design and manufacture of stainless steel tanks, B750L steel for automobile components processing systems and equipment for the food, dairy, beverage, chemical, pharmaceutical, biotechnology, and pure water industries. They also sent the inspection team come our company and visited our production line. After using our stainless steel plate, the customer was very satisfied with our products.

At present, the cutting thickness limit of laser cutting is 20 mm. However, it should be noted that oxygen will be added into the laser beam to cut 20 mm thick B750L steel for automobile components steel plate, which will form a thin oxide film on the cutting surface, which may affect the cutting quality, Therefore, attention should be paid to this point to avoid problems.

The weldability of B750L steel for automobile components is good. It means that under certain process and construction conditions, B750L steel for automobile components can obtain good performance after welding. Weldability is a measure of the hot workability of steel. Weldability can be divided into weldability in construction and weldability in use. Weldability in construction refers to the sensitivity of cracking in weld metal and near seam zone, and hardening sensitivity of steel in near seam zone. Good weldability means that under certain welding process conditions, the weld metal and steel near the seam do not produce cracks. Weldability in use means that the mechanical properties of weld and HAZ steel are not lower than those of base metal.

Customer concept: customer first. Guided by market changes and guided by customer needs, we design the optimal product solutions and provide the best after-sales service. Partners: to reach a balance of interests with all stakeholders, to build a harmonious coexistence and win-win cooperation.

Leave a message