machinability of S420MC steel for automotive industry

The company has a mature technical team whose reponsibility is to design the drawing, choose suitable material and evaluate the whole production processaccording to customers’ requirement. The company is led by talents and technology, and compre

The company has a mature technical team whose reponsibility is to design the drawing, choose suitable material and evaluate the whole production processaccording to customers’ requirement. The company is led by talents and technology, and comprehensively promotes its six business segments like steel material supply, precision steel casting, environmental protection equipment, household appliance, S420MC steel for automotive industry steel structures and oil tank projects. Seeking new developments in new technology and business areas, and fostering a large number of industry-leading, international-level projects.

S420MC steel for automotive industry, 45Mn2 steel is a kind of alloy structural steel. 45Mn2 steel is made of high-quality carbon structural steel with proper addition of manganese. 45Mn2 steel belongs to the medium carbon quenched and tempered steel in alloy structural steel. The parts made with 45Mn2 steel can obtain high strength and good toughness after quenching and tempering at high temperature. That is to say, 45Mn2 steel has good comprehensive mechanical properties and is often used to manufacture shafts, connecting rods, fasteners which bear large loads.

The main applications of normalizing are as follows:①For low carbon steel, S420MC steel for automotive industry. The hardness of low carbon steel after normalizing is slightly higher than that after annealing, and the toughness is also better, so normalizing can be used as the pretreatment of cutting.②For medium carbon steel, normalizing can be used as the final heat treatment instead of quenching and tempering treatment, or as the preparation treatment before surface quenching by induction heating.③Normalizing can be used in tool steel, bearing steel, carburizing steel and so on, which can eliminate or inhibit the formation of network carbide, thus obtaining the good microstructure needed for spheroidizing annealing.④Normalizing can refine the cast structure and improve the machinability of steel castings.

20 # material is a high-quality low-carbon carbon steel, cold-extruded, carburized and hardened steel. S420MC steel for automotive industry, 20 # material has low strength, good toughness, plasticity and good weldability. Chemical composition of 20 # round steel bar: C: 0.17 ~ 0.23, Si: 0.17 ~ 0.37, Mn: 0.35 ~ 0.65, S: ≤0.035, P: ≤0.035, Cr: ≤0.25, Ni: ≤0.30, Cu: ≤0.25. 20# carbon steel mechanical properties: Shear strength 275 ~ 392MPa, Tensile strength is 253 ~ 500MPa, elongation min. 25%.

The company attaches great importance to logistics services, sets up our own transport truck fleet, improves customer response capacity through the improvement of logistics capacity, and further reduces costs. Customers ordering S420MC steel for automotive industry steel from our company can not only enjoy the service of fast delivery, but also enjoy lower transportation costs. Fast, accurate, simple and efficient has always been our principle.

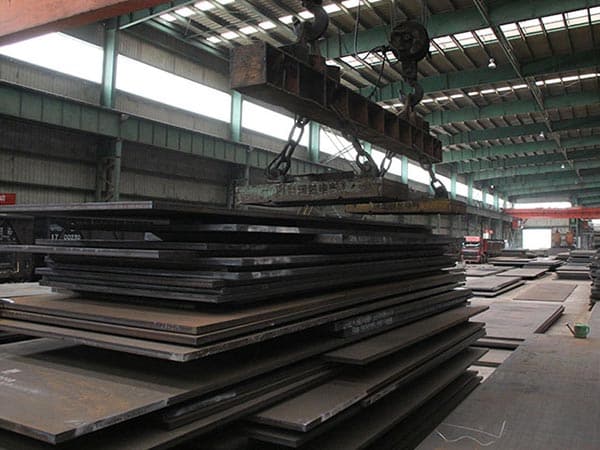

Over the years, the company has maintained long-term stable business relationships with major domestic steel mills and foreign steel companies. The company's main boiler and pressure vessel steel plates, low alloy high-strength steel plates, wear-resistant steel plates, corrosion-resistant steel plates, S420MC steel for automotive industry bridge steel plates , strucural teel plates, steel plates for alloy structures, mold steel plates, steel plates for shipbuilding and production platforms, composite steel plates, steel plates for oil and gas pipelines. Welcome to come China and visit our S420MC steel for automotive industry production line.

Leave a message