Flame cutting is suitable for medium and thick s420 steel mechanical properties cutting

BEBON is a large steel group with finance department, production department, sales team, technical department, quality control department, logistics department and after-sales service team. We are committed to creating a various culture system with its ow

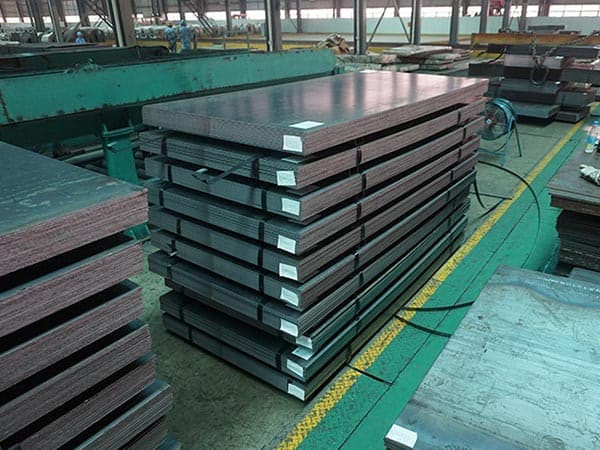

BEBON is a large steel group with finance department, production department, sales team, technical department, quality control department, logistics department and after-sales service team. We are committed to creating a various culture system with its own characteristics, and work hard to create a first-class steel plate company in China. Based on the business philosophy of quality-oriented and strengthened management, the company continues to develop in this industry.

Low carbon alloy steel, the total amount of alloy elements is generally ≦3%; the low carbon alloy steel strength is significantly higher than that of carbon steel, with better plasticity and toughness, and weldability is acceptable; low alloy steel includes carbon manganese series, carbon manganese vanadium series, s420 steel mechanical properties chromium molybdenum series, chromium molybdenum vanadium series. Molybdenum and chromium molybdenum vanadium alloy steels are commonly used as materials for hydrogen corrosion resistance, high temperature sulfur or hydrogen sulfide corrosion resistance and heat resistance (sub high temperature).

Main uses of s420 steel mechanical properties, special steel. First, special steel is used for bearing manufacturing. Second, the special steel is used for mold manufacturing, which can withstand high temperature very well, and has excellent repeated use performance, which makes the mold quality excellent also. Third, the special steel is used in the manufacture of spring plates, and the chassis of some cars need to use the spring plate, which has good elasticity and flexibility. Fourth, the special steel is used in the aerospace industry. Fifth, the special steel is used to manufacture hardware products such as knives and drill bits.

Tempering includes high temperature tempering, medium temperature tempering and low temperature tempering. Tempering means to reheat the s420 steel mechanical properties quenched steel to a certain temperature and then cool it in a certain way. Tempering can reduce or eliminate the internal stress produced by quenching, reduce the hardness and strength, and improve the ductility or toughness of steel. After s420 steel mechanical properties quenching, the workpiece should be tempered in time, and the required mechanical properties can be obtained through the combination of quenching and tempering.

Welcome customers to visit our company, we specialize in steel products, adhere to the s420 steel mechanical properties quality first standard, and do not forget to provide customers with the best quality products and services. Our product quality office is the best, and our s420 steel mechanical properties price is also very advantageous. Welcome to purchase steel products from our company.

The company always adheres to the concept of green production, follows the development path of innovation, transformation and improvement, and has carried out in-depth cooperation with Zhengzhou University and other scientific research institutes, planning from a high starting point, strict standard design, and successfully implementing engineering projects With nearly 20 research and development projects, the company's production technology and equipment are at the forefront of the industry, and indicators such as environmental protection, energy consumption, cost, and resource utilization have reached the advanced level in the industry.

Over the years, the company has strived for perfection, being well-received. By virtue of stable product performance, high-quality engineering effects and perfect service system, we have won the trust of many customers, and our engineering cases and after-sales service systems are spread all over the world. We regularly conduct quality tracking and return visits by phone and email, listen to customers' opinions, and continuously improve service quality.

Leave a message