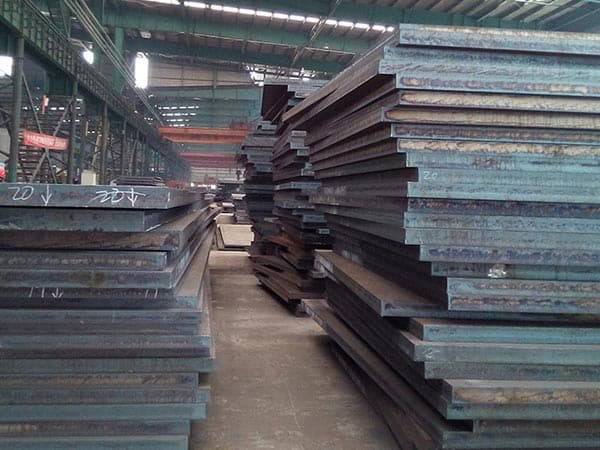

Export ZQS700L automobile structure steel plate carbon to Morocco with 1600 tons

The company regularly holds sales elites to share experiences, to promote the rapid growth of colleagues, and achieve the company and employees. The company conducts employee skill training and related knowledge video learning from time to time. All these

The company regularly holds sales elites to share experiences, to promote the rapid growth of colleagues, and achieve the company and employees. The company conducts employee skill training and related knowledge video learning from time to time. All these things is to improve the employees' skills and literacy, and reflects its own value. It has always been the pursuit of BBN steel to enhance the employee’s ability and keep up with the times.

Spring steel, as we can clearly know from its name, is one of the main materials used to make springs and special alloy steel for other elastic components. ZQS700L automobile structure steel plate, Spring steel has good comprehensive properties, it has heat resistance, low temperature resistance, oxidation resistance, corrosion resistance and so on advantages. Compared with alloy spring steel, carbon spring steel has less advantages, but its price is cheaper, and the source of raw materials is convenient. The disadvantage of carbon spring steel is that the elastic limit is low and it is easy to lose elasticity after repeated deformation.

Laser cutting ZQS700L automobile structure steel plate has no burr, wrinkle and precision is high. It is superior to plasma cutting. Laser cutting has good cutting quality, narrow cutting width (generally 0.1-0.5m m), high accuracy (generally 0.1-0.4mm hole center distance error, 0.1-0.5mm contour dimension error), good surface roughness (generally Ra is 12.5-25μm), and the ZQS700L automobile structure steel plate cutting seam can be welded without further processing. Fast cutting speed: for example, with 2kW laser power, the cutting speed of 8mm thick carbon steel is 1.6m/min.

Square hollow section S355J2H to Turkey. In January of 2015, our customer from Turkey chose us as their supplier of seamless RHS EN10219 S355J2H with a trail order of 120 tons. They required DNV test for the MTC and each tube. DNV inspector tested all the tubes and MTC. When our customer received the reports, they gave us a second order of 852.5 tons. Since then we maintain a long time cooperation relationship.

Leave a message