en 10149-2 pdf free download for boiler body

The company adheres to the en 10149-2 pdf free download external market, internal management, quality and efficiency oriented development path, and has achieved good economic and social benefits. With strong financial strength, advanced management experie

The company adheres to the EN 10149-2 pdf free download external market, internal management, quality and efficiency oriented development path, and has achieved good economic and social benefits. With strong financial strength, advanced management experience, excellent sales service, strict quality management system and scientific overall marketing means, we will work hand in hand with you for common development. We are making all efforts working on the optimization of en 10149-2 pdf free download quality and price and best service for all our customers.

Comparison of stainless steel 304 and 304L: The main difference between 304L and 304 is the carbon content. The carbon content of 304 is less than or equal to 0.08, and the carbon content of 304L is 0.03 max. Secondly, en 10149-2 pdf free download, 304 stainless steel is a versatile stainless steel, which is widely used in making equipment and parts that require good comprehensive performance (corrosion resistance and formability), and 304L is a variant of 304 stainless steel with a low carbon content, which is used for Welding occasions.

In 2016. Our company offer 1200 tons API 5L GR.B hot rolled coil to Bangladesh——100 tons for 3.9*625mm, and 1100 tons for 7*683mm. It is one tender project, we get the tender at the end of 2015, and arrange the production in 2016. They required the tolerance of thickness is +0.1/-0.2mm, and width tolerance is +/-0.5mm, which is a very high requirement for coil tolerance, but our mill handling this very well. and our Q/C department witness all of the process.

The weldability of en 10149-2 pdf free download is good. It means that under certain process and construction conditions, en 10149-2 pdf free download can obtain good performance after welding. Weldability is a measure of the hot workability of steel. Weldability can be divided into weldability in construction and weldability in use. Weldability in construction refers to the sensitivity of cracking in weld metal and near seam zone, and hardening sensitivity of steel in near seam zone. Good weldability means that under certain welding process conditions, the weld metal and steel near the seam do not produce cracks. Weldability in use means that the mechanical properties of weld and HAZ steel are not lower than those of base metal.

We should focus on the main problems to be solved and pay attention to efficiency. After receiving the user's quality objection report data, the possible causes, responsible units, compensation amount, etc. of the problem shall be judged based on experience. To have a clear service plan, to be clear about what your main problem is, what technical support is needed, these should be prepared.

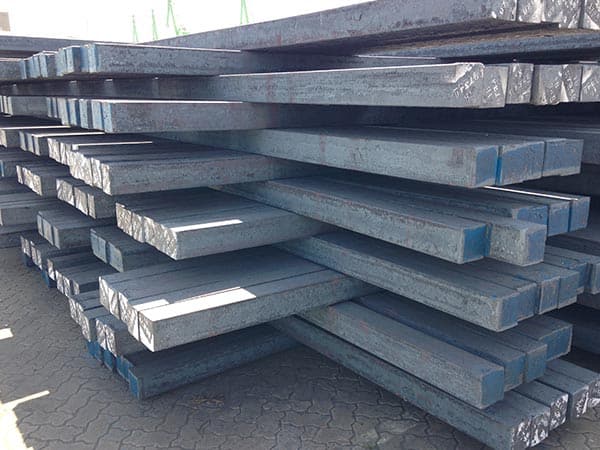

We have huge stocks for carbon steel plates, high strength low alloy steel materials, weather resistant steel sheets, wear resistant steel plates, boiler plates, pipeline steel, etc. Those stocks can be delivered within 10 days after deposit. We update en 10149-2 pdf free download stock list regularly. But the stock changes quickly. It needs to check with warehouse specially when you have urgent needs. Welcome to contact us and book steel materials stocks.

Leave a message