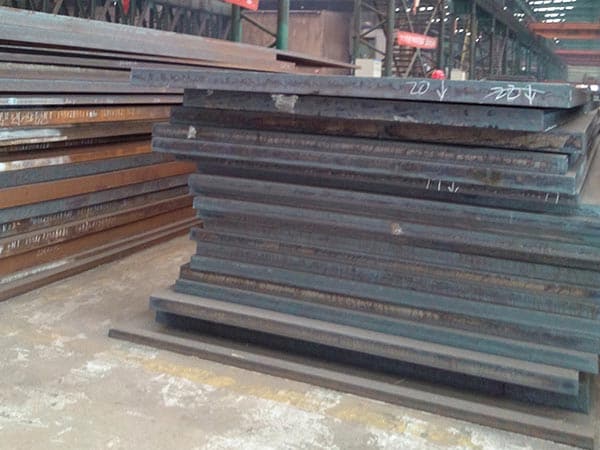

en 10149 2 hot rolled pickled and oiled steel coil in gas & oil plants industry use

Our company is a specialized technical support and after-sales service organization - customer service center. At the same time, we have provided excellent technical en 10149 2 hot rolled pickled and oiled steel coil personnel and strong technical support

Our company is a specialized technical support and after-sales service organization - customer service center. At the same time, we have provided excellent technical EN 10149 2 hot rolled pickled and oiled steel coil personnel and strong technical support for our company, and cultivated an excellent after-sales team for our company. Our company will appoint a full-time service manager to be responsible for the unified coordination of technical support and en 10149 2 hot rolled pickled and oiled steel coil after-sales service of the project.

The wear-resistant plate en 10149 2 hot rolled pickled and oiled steel coil shows good wear resistance: the chemical composition of the alloy layer contains 4-5% carbon and 25-30% chromium. The volume fraction of Cr7C3 carbide in the metallographic structure is more than 50%, the macro hardness is HRC56-62, and the hardness of chromium carbide is HV1400-1800. Because of the vertical distribution of carbides in the wear direction, the wear resistance of the cast alloy with the same composition and en 10149 2 hot rolled pickled and oiled steel coil hardness is more than twice as that of the cast alloy with the same composition and hardness. Compared with several typical materials, the wear resistance is as follows: (1) compared with low carbon steel; 20-25:1 (2) with as cast high chromium cast iron; 1.5-2.5:1.

The cold bending method is mainly used to produce cold-formed section steel and welded pipe. The cold bending method is to bend the steel strip or steel plate into various cross-section shapes by the cold bending machine in the cold state. If the en 10149 2 hot rolled pickled and oiled steel coil steel pipe is bent into a circular, square or other hollow shape and welded by a proper welding method, it is a welded pipe. The advantages of cold bending: first, the cold-formed section steel is light in weight and large in bearing capacity, and it can save metal by replacing the hot-rolled section steel; second, it can produce all kinds of en 10149 2 hot rolled pickled and oiled steel coil extremely thin, extremely wide and complex section steel which can not be produced by hot rolling.

The Indonesia INKA is the only train carriage maker for railway industry in Indonesia. We cooperated with them since 2012 and supply them SPA-H steel. The SPA-H steel is used by them to fabricate train carriage. We have huge stocks for SPA-H steel and can arrange delivery for them in short time after receiving order. Meanwhile, our product en 10149 2 hot rolled pickled and oiled steel coil quality has passed their test for so many times use. Therefore, they trust us and give us repeat orders regularly. And we also do our best to support them and have never let them down though past cooperations.

Leave a message