BS700MC steels for automobile structure delivered to Georgia

We supply more than 2,000 tons of high strength BS700MC steels for automobile structure low alloy steel coils to support the construction of Iraq's thermal power equipment projects. As a "Belt and Road" construction project, the Iraqi therm

We supply more than 2,000 tons of high strength BS700MC steels for automobile structure low alloy steel coils to support the construction of Iraq's thermal power equipment projects. As a "Belt and Road" construction project, the Iraqi thermal power generation project has high requirements on the quality of steel for power generation equipment. In particular, the flue gas baffle door sealing system of BS700MC steels for automobile structure thermal power plants has extremely strict requirements on the composition, yield strength and tensile strength of steel. Our hot rolled low alloy steel coils have won the favor of customers for their excellent mechanical properties, standard sizes, and beautiful shapes.

In line with the service concept of "honesty first, customer first" and the service tenet of "all for customer satisfaction", the company adopts the acceptance and response mode of combining manual and automatic, and accepts the diversified service demands of customer business consultation, complaint declaration, business acceptance, etc. through telephone, fax, e-mail, visit, letter, etc.

ANDRITZ GROUP is the world's leading industrial group, with 29500 employees and more than 280 branches in more than 40 countries. We have cooperated with their Mexico company for many years about S355J2+N steel plates and cutting sectors. The S355J2+N steel plates BS700MC steels for automobile structure need to cut according to the drawing by standard tolerance, UT, MT and dimension request. The final application of the S355J2+N steel plates and cutting sectors are for assembling hydraulic machine.

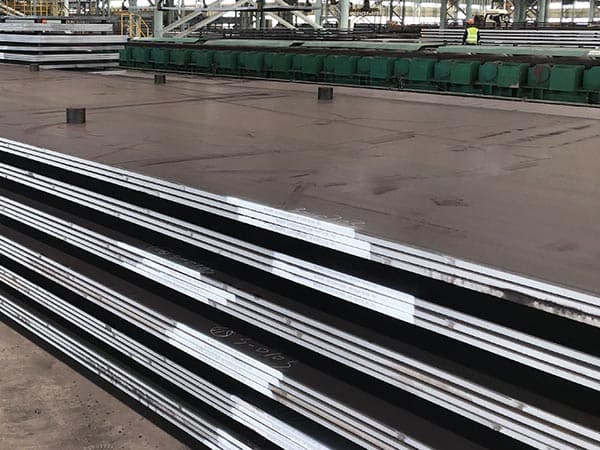

Rolling of steel plates is the core of the entire steel rolling production process. The billet is deformed by rolling. The rolling process plays a decisive role in product quality. The quality requirements of rolled BS700MC steels for automobile structure products include the three aspects of product geometry and dimensional accuracy, internal organization and performance, and product finish. Finishing: It is the last process in the BS700MC steels for automobile structure rolling process, and it is also a more complicated process. It plays a final role in guaranteeing the quality of the product.

The bridge steel plate is mainly used for erecting railway bridges, highway bridges, sea crossing bridges, etc. The bridge steel plate is required to have high strength and toughness, bear the load and impact of rolling stock, and have good fatigue resistance, certain low temperature toughness and atmospheric corrosion resistance. The bridge steel plate BS700MC steels for automobile structure should also have good welding performance and low notch sensitivity. If you want to have a more comprehensive and detailed understanding of bridge steel plate, welcome to visit our official website for consultation.

On November 1st, our company organized some of company staff to visit Zhengzhou Children Welfare Institute, and gave children cookies and toys, as well as concerns to the Children. With the development of the society, disabled children gets increasing concerns and help from all walks of life. Fortunately, Chinese Government gives high concern to the handicapped children and has built Children Welfare Institutes all over the country to guarantee their lives.

Leave a message