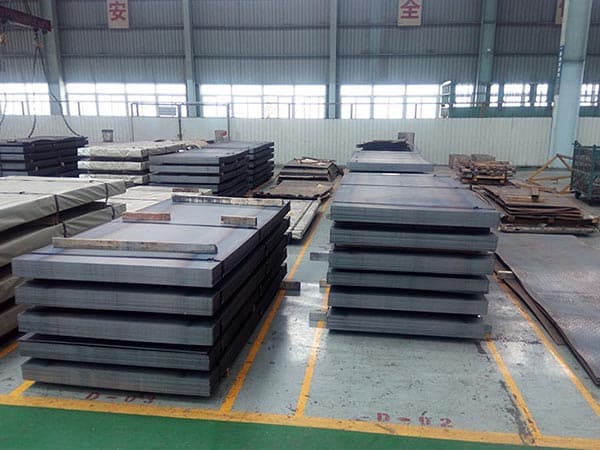

1.0976 hot-rolled steel shipped to Nigeria 2018

In 2019, the output of pig iron in the world was 1.265 billion tons, with China accounting for 64%; the overseas output accounted for 36% (460 million tons), ranking 86.982 million tons of EU 28 countries, 74.907 million tons of Japan, 74.099 million tons

In 2019, the output of pig iron in the world was 1.265 billion tons, with China accounting for 64%; the overseas output accounted for 36% (460 million tons), ranking 86.982 million tons of EU 28 countries, 74.907 million tons of Japan, 74.099 million tons of India, 73.264 million tons of CIS, and 1.0976 hot-rolled steel 47.521 million tons of South Korea. In the first quarter, the global output was 311 million tons, with a year-on-year decrease of 0.5%, with China 1.0976 hot-rolled steel increasing by 2.4%; the overseas output decreased by 5.4%, Among them, EU decreased by 9.2%, Japan increased by 1.3%, India decreased by 7.7%, CIS increased by 2.1%, and South Korea decreased by 4%.

The shipping department of the company arranges shipping booking for customers' goods in advance, and makes good matching with inland transportation. Effectively manage and follow up the customer's shipping schedule and give feedback to customers in time. At the same time, the shipping department has a keen insight into the shipping market in different periods to reduce the transportation cost for the company and customers.

Good news: The largest steel importer in Nigeria ordered 4068 tons API 5L X52Q PSL2 3LPE seamless pipes and also ordered 8 pcs 42699.6 m³big diameter Crude oil storage doom roof tank in A537CL2 steel grade. In Sep 2019, This Nigeria client visited our company and factory, they were very satisfied with our company's quality control,production capacity and service. We also have reached a agreement for Phase II Project, It is also with another 10,000 tons APl 5L X52Q PSL2 3LPE seamless pipes.

A plasma cutter uses a stream of compressed gas (air, nitrogen, argon, etc.) and a consumable wire electrode as the two primary feedstocks of the steel cutting process. The electrode sends a high electrical charge through the gas, raising its temperature to the point of ionization to generate extremely hot plasma (~20,000°C). This plasma is directed through the cutting tip to create a highly focussed beam, with velocities approaching the speed of sound.

High wear resistance: fully automatic CNC stacking equipment, independent of manual 1.0976 hot-rolled steel welding technology, produces fully qualified high-quality products. Special automatic welding technology enables the chromium content of wear-resistant layer to be controlled at more than 28%, and the 1.0976 hot-rolled steel hardness is between 58-62, which fully ensures that our wear-resistant layer has continuous good and balanced wear resistance. The wear test in metallurgy, cement and other industries shows that the wear resistance of the wear-resistant layer of the surfacing composite 1.0976 hot-rolled steel wear-resistant steel plate is more than 30 times that of the 16Mn plate with the same thickness.

The company revolves around the long-term strategy of "building a quality base and building a century-long BEBON", adheres to the development ideas of innovation, transformation, and improvement, vigorously promotes transformation and upgrading, structural adjustment, energy conservation and emission reduction, and strives to create high-quality steel with strong core competitiveness and distinctive features The production base has become a green steel city with intensive land use, clean production, efficient use of resources, harmonious and friendly production and environment, business and society, and BEBON characteristics.

Leave a message