Top 10 S355MC composition manufacturers

Established in 2014, Steel Safety Day was set up to reinforce awareness of the five most common causes of safety incidents and to create a safer working environment across the entire steel industry worldwide. By focusing every year on the five causes - mo

Established in 2014, Steel Safety Day was set up to reinforce awareness of the five most common causes of safety incidents and to create a safer working environment across the entire steel industry worldwide. By focusing every year on the five causes - moving machinery, working at heights, falling objects, on-site traffic and S355MC composition process safety incidents - worldsteel intends to set up a continuous improvement process and reiterate its commitment to the safety and health of the people who work in the S355MC composition industry.

For employees' development, the company's transformation and development provides employees with a broad career development platform. The company needs "lion-type" entrepreneurial leaders who are full of entrepreneurial enthusiasm and dare to self-renovate. They also need a large number of professional and professional high-quality talents, and employees can get full capacity to display opportunities.

In the manufacturing process of boiler pressure components, raw materials must undergo complex processing deformation and welding, so the steel used to manufacture the boiler must also have good process performance. All materials S355MC composition used to manufacture pressure parts must conform to the relevant national standards for boiler steel. The defects such as delamination, non-metallic inclusion, porosity and looseness in the steel shall be as few as possible, and white spots and cracks are not allowed.

The company uses outsourced logistics operations. Our cooperated professional third-party logistics providers use the advantages of large-scale production and cost advantages to achieve cost savings by increasing the utilization of resources in each link, so that we can benefit from the separation of cost structure. Therefore, we can also provide customers with better, faster and more efficient cargo transportation, delivery, and lower freight costs.

After the steel plate is produced from the original factory, it will pass through a series of transportation and storage links and then be delivered to the processing workshop. During this period of time, the steel plate surface will contact with the air continuously, which will inevitably produce a layer of oxide skin. The oxide skin is a difficulty in the treatment process. It has high melting point, is not easy to burn and dissolve, increases preheating time, reduces cutting speed. Therefore, the surface of the S355MC composition plate should be derusted before cutting.

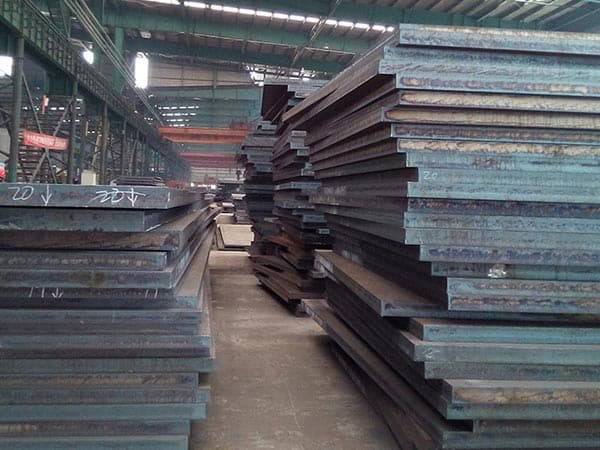

If you want to find wear resistant steel plates or abrasion resistant steel supplier and exporter in China, please visit us. We are one of the leading S355MC composition wear resistant steel plates manufactures and stock keepers. We have large stocks for wear resistant steel plates of various grades and dimension. We can not only send offer at the first time, but can also provide technical support and give you professional suggestions and answers about NM400 S355MC composition steel specifications, difference between hardox 400 and AR400 and so on question about wear resistant steel plates. Come on! Just call us or send email.

Compared with other fast-moving consumer goods, steel consumption is obviously different, with a wide range of use and a long service life. Therefore, the quality and service of steel materials are particularly important. Service is always one of our top concerns, especially after-sales service. We have mature after-sales service team, and can help you solve problems professionally during application of the steel materials.

Leave a message