Surface treatment method for BS700MC heat treatment before cutting

Since the foundation of the company, the Spring Festival Gala is an annual activity held at the end of the year. Now it is a part of the BBN company culture to enrich the employee's life. The annual Spring Festival Gala in 2019 was held on January 20

Since the foundation of the company, the Spring Festival Gala is an annual activity held at the end of the year. Now it is a part of the BBN company culture to enrich the employee's life. The annual Spring Festival Gala in 2019 was held on January 20, 2020. There are opening ceremony, leader's speech, BBN steel performance, awards for outstanding employees, lucky draw, party game, curtain call, company group photo, annual Gala dinner and other links.

Welded steel pipes are made by crimping steel plates, bending them into a circle, and then welding the joints together. Seamless steel pipe is directly processed by round steel piercing or hot rolling process, so there is no weld on the outer surface. The performance of seamless steel pipe is better than that of welded steel pipe, and the price of seamless steel pipe is also higher. There are some differences in chemical composition between BS700MC heat treatment, welded steel pipe and seamless steel pipe. The material of welded steel pipe contains the chemical composition suitable for welding.

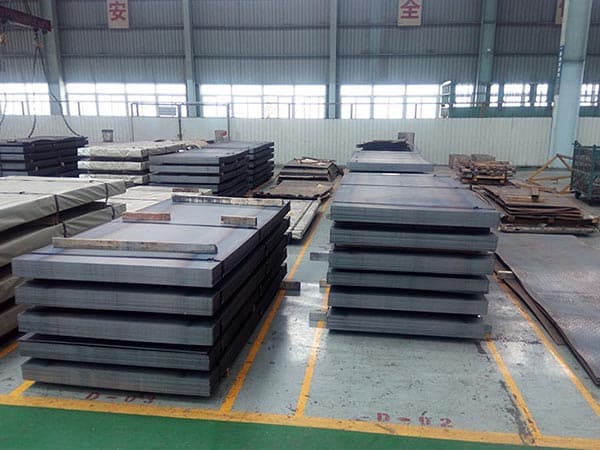

10 to 20mm thick BS700MC heat treatment product: 10*2200*7200, 10*2200*8000, 12*2000*11850, 12.5*2900*11000, 12.9*2987*10384, 13.6*2940*11455, 14*2000*10000, 14*2000*11181, 14*2000*13500, 14*2070*9060, 14*2200*10030, 15*2200*10270, 15*2500*10000, 15*2992*10185, 16*1500*9340, 16*1800*6000, 16*2000*10713, 16*2120*6080, 16*2200*10000, 16*2230*7650, 18.5*2320*6600, 20*1400*11400, 20*2100*7000.

20G steel is a common carbon steel used to manufacture boilers. The performance of 20G steel is basically the same as that of 20# steel. The requirements for impact toughness, strain aging impact value and cold bending of 20G steel are increased. The yield ratio of 20G steel is slightly higher, and certain fatigue and corrosion resistance are required for BS700MC heat treatment steel to ensure the safe operation of boilers. 20G steel is suitable for manufacturing marine boilers, steam boilers and other boiler accessories with pressure less than 6Mpa and wall temperature less than 450 ℃.

With a high-quality and complete after-sales service system, the company solves the user's hindrance and improves the reliability of steel BS700MC heat treatment product quality. Reaching every corner of the globe with professional services, users anywhere can get thoughtful and detailed services form us is our pursue. We promise all our steel materials are manufactured and tested in accordance with responding standards. We will take full responsibility for the quality of the steel materials we provide.

Expect in the BS700MC heat treatment goods regardless quality be still on the price after-sales service we all will keep in the middle of go together of advantage position real attain the ream customer satisfaction.Our advantage is: experienced craftsmen BS700MC heat treatment product development technology, excellent production team, hand strict quality control, sales and after-sales service.

Leave a message