Supply the EN 10149-2 steel coil sheet/coil mechaical properties

EN 10149-2 steel coil, No.45 seamless pipe belongs to high strength medium carbon steel, with certain plasticity and toughness, high strength and good machinability. Good comprehensive mechanical properties can be obtained by quenching and tempering treat

EN 10149-2 steel coil, No.45 seamless pipe belongs to high strength medium carbon steel, with certain plasticity and toughness, high strength and good machinability. Good comprehensive mechanical properties can be obtained by quenching and tempering treatment. In addition, the hardenability of No.45 seamless pipe is poor, and the water quenching is easy to produce cracks. After quenching and tempering, the small and medium-sized parts can obtain better toughness and higher hardness. For large parts (the section size is more than 80mm), normalizing treatment is appropriate. But the weldability of No.45 steel is poor. The weldment should be preheated before welding and annealed after welding to eliminate welding stress.

Main uses of EN 10149-2 steel coil, special steel. First, special steel is used for bearing manufacturing. Second, the special steel is used for mold manufacturing, which can withstand high temperature very well, and has excellent repeated use performance, which makes the mold quality excellent also. Third, the special steel is used in the manufacture of spring plates, and the chassis of some cars need to use the spring plate, which has good elasticity and flexibility. Fourth, the special steel is used in the aerospace industry. Fifth, the special steel is used to manufacture hardware products such as knives and drill bits.

Rolling steel is the process of pressing to change the shape of the ingot and billet between the rotating rolls. The so-called steel rolling process is a combination of a series of steel rolling processes. The entire rolling production process is always composed of the following EN 10149-2 steel coil basic processes: ① billet preparation:Including the cleaning of surface defects, the removal of surface scale and the pre-heat treatment of billets. ② billet heating ③ steel rolling: it is the core of the entire rolling production process. ④ Finishing.

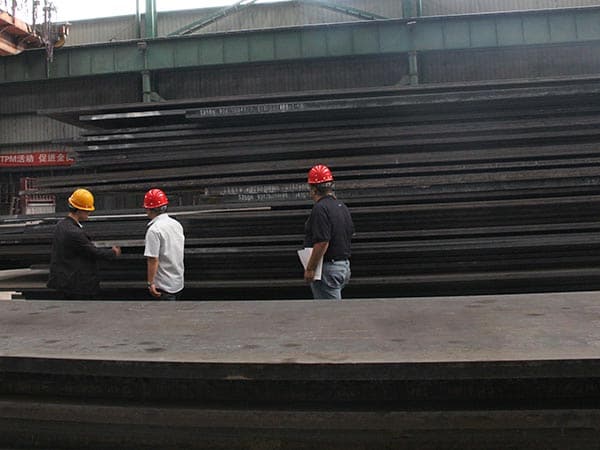

Our company has been established for 20 years and has accumulated rich experience in steel products. At the same time, it is often exported to Southeast Asia, Africa, South America and other countries. So you can rest assured that our EN 10149-2 steel coil products and our prices are very favorable. Because we have our own factory, there is no other cost, we can also carry out machining and so on.

Provide special product requirements to meet the personalized needs of customers. The EN 10149-2 steel coil company arranges production and shipment strictly according to the contract, and guarantees to supply goods according to the time agreed in the contract. Provide professional consultation: we guarantee to answer any professional and EN 10149-2 steel coil technical questions raised by users within 1 hour; provide detailed information.

Leave a message