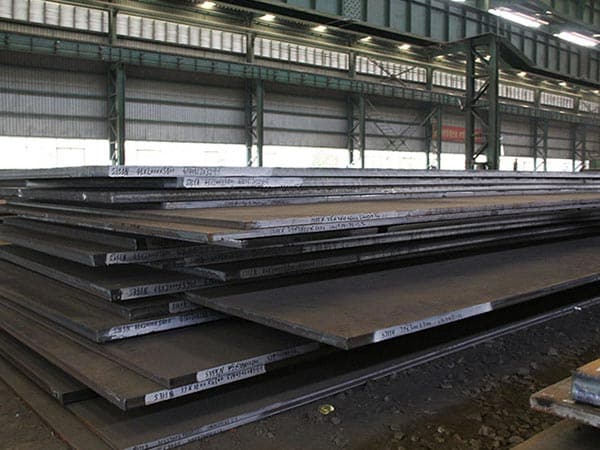

structure steel plate s700m quality and thickness range

Gas cylinder steel plate is used to manufacture the material which can be used repeatedly to manufacture liquefied petroleum gas cylinders with working temperature of 40-60 ℃, structure steel plate s700m test pressure of 2.36 MPa, water volume of 23.5L, 3

Gas cylinder steel plate is used to manufacture the material which can be used repeatedly to manufacture liquefied petroleum gas cylinders with working temperature of 40-60 ℃, structure steel plate s700m test pressure of 2.36 MPa, water volume of 23.5L, 35.5L, 118L.

Our company specializes in the production of steel plates, steel coil, steel sections, welded pipes and seamless pipes products, sales of GB, ASME, ASTM, JIS, DIN, EN, API and other standards and specifications of steel structure steel plate s700m and deep-processed products, facing the domestic and foreign markets, welcome to call for inquiries. It is a modern high-tech professional enterprise integrating scientific research, production and sales.

According to the different heating and melting methods of wear-resistant steel plate, structure steel plate s700m, wear-resistant steel plate also has its own melting welding method. Cast welding is an earlier welding method, which uses the heat released during the oxidation of thermite or magnesium thermite to melt metal: its characteristics are simple equipment and operation, but for wear-resistant steel plate, the welding quality is not high. It is only used to repair the workpiece.

Compared with the common pressure vessel, the pressure parts of the boiler not only bear the pressure, but also suffer from the radiation and erosion of the high temperature flue gas. Once the pressure components of the boiler fail in operation, it will cause extremely serious consequences. Therefore, the structure steel plate s700m, steel materials used to manufacture the pressure components of the boiler must have enough high strength, plasticity, toughness, fatigue resistance and corrosion resistance, as well as good high-temperature mechanical properties for high-temperature components.

The company has passed the ISO9001: 2008 quality system certification, strictly implemented the ISO9001 quality management system. Besides, we have continuously improved the after-sales service network to make every effort to provide more convenient, accurate and faster services for all customers. We will supervise the production, control the quality in the factory, Inspect the cargo before shipment, Issue the test report to sales department. From the steel prodcution to steel delivery, we always focus the whole process.

Leave a message