S960MC quality and thickness range

Our company is China's 10th largest supplier & Exporter of stainless steel, carbon steel plate and section, alloy steel plate and pipes. We are specialized in stocking & distributing various Stainless Steel, carbon steel plates, S960MC angle

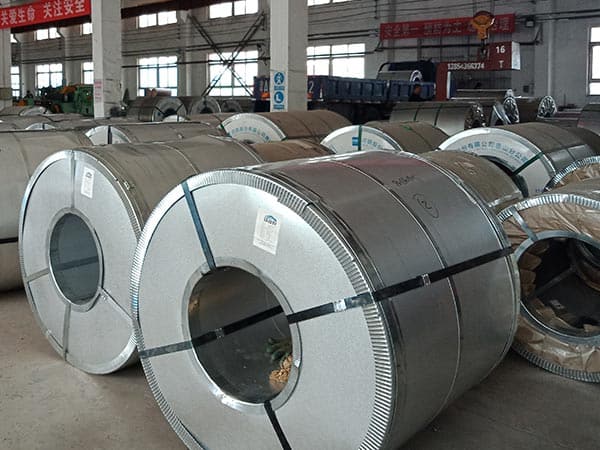

Our company is China's 10th largest supplier & Exporter of stainless steel, carbon steel plate and section, alloy steel plate and pipes. We are specialized in stocking & distributing various Stainless Steel, carbon steel plates, S960MC angle steel, H beam steel to worldwide for specific & urgent requirements. We have a fully advanced and modernized warehouse that stores tonnes of our value-adding S960MC products, which we source out from the mills that are compliant with the universal guidelines for plate production.

The yield strength of A40, D40, E40 and F40 S960MC is not less than 390N/mm^2, and the tensile strength is 510~660N/mm^2. A, D, E and F respectively indicate that they can be at 0° and -20 ° respectively. Impact toughness S960MC that can be achieved at -40℃, -60℃.

S960MC, High-strength wear-resistant plates have outstanding performance advantages. First of all, the high-strength wear-resistant plates get their name because their wear resistance is very good, and the degree of wear will not be prominent. Secondly, the corrosion resistance of the high-strength wear-resistant plate is very good. General chemical plants have many corrosive liquids, and the high-strength wear-resistant plates can be used as the floor to reduce risk of accidents.

Flame cutting is a common hot cutting method in modern iron and steel industry. It is also a very important part in the process of iron and S960MC steel processing. Flame cutting can cut very thick carbon steel, its cutting range is very wide, can cut 6mm-200mm thick steel plate. In cutting thick and S960MC medium plates, flame cutting plays an important role. And with its price advantage, flame cutting has always occupied a certain market share in thin plate cutting also.

S960MC, 27SiMn material has high strength and wear resistance, high hardenability, medium plasticity during cold deformation, good machinability and fair weldability. It is mostly used after quenching and tempering, and can also be used in normalizing or hot rolling state. 27SiMn material chemical elements: C: 0.24-0.32, Si: 1.10-1.40, Mn: 1.10-1.40. 27SiMn material mechanical properties: tensile strength 980 MPa; yield strength: 835 MPa; elongation after fracture: 12%; impact energy: 39J. 27SiMn material can be used to make hot stamping parts with high toughness and high wear resistance, which do not need heat treatment or normalizing, such as tractor track pins.

Both parties shall confirm the S960MC material object and the quality of the products, confirm the reasons for the defects and the quality of the products, and sign the quality inspection agreement. Major quality objections shall be reported to relevant leaders in a timely manner, and shall be discussed and solved with the S960MC steel plant.

Leave a message