S500MC thermomechanically rolled steels should be promoted and utilized more

Wear resistant steel plate has excellent low temperature toughness, so it can be used in large welding structure and low temperature environment. Moreover, there are many kinds of wear-resistant steel plate, S500MC thermomechanically rolled steels in oper

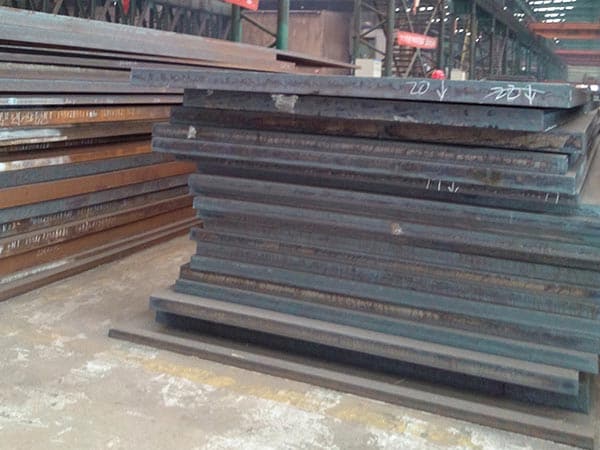

Wear resistant steel plate has excellent low temperature toughness, so it can be used in large welding structure and low temperature environment. Moreover, there are many kinds of wear-resistant steel plate, S500MC thermomechanically rolled steels in operation control, especially in the factory building. Wear resistant steel plate is widely used in construction and steel pipe industry, which is one of the most important products in the industry. It is composed of low-carbon steel plate and alloy wear-resistant layer. The alloy wear-resistant layer is generally 1 / 3-1 / 2 of the total thickness.

The company is committed to providing customers with high-quality and low-cost S500MC thermomechanically rolled steels steel products as the goal, striving to create value for customers as its own responsibility. With advanced Kaiping processing equipment and strong logistics distribution system, the company can meet the needs of customers at any time. The company has the advantages of S500MC thermomechanically rolled steels complete specifications, low price and fast distribution, With the service concept of keeping promise and valuing quality, it has won the trust and unanimous praise of the majority of users. The scale and strength of the enterprise is in the forefront of domestic metal material business units.

During the welding of hardfacing wear-resistant steel plate, S500MC thermomechanically rolled steels, the welding shall be carried out in strict accordance with the drawing, welding process and relevant standards. Follow the welding sequence of first welding the base layer, then welding the transition layer, and then welding the multiple layer. In order to prevent adhesion of welding spatter, anti spatter coating should be applied within 100 mm on both sides of groove of stainless steel clad plate before welding.

Peritectic reaction often occurs in the process of cooling and solidification of wear-resistant steel plate, S500MC thermomechanically rolled steels, and accompanied by this reaction, there will be greater volume change and linear shrinkage, which is mainly due to the hot cracking of continuous casting slab in the casting process. In the mold, the heat load transmitted from the billet is too much or uneven around the meniscus of molten steel, resulting in uneven heating, which is more likely to produce longitudinal cracks.

We guarantee to provide all technical data required by users within one hour to provide reasonable quotation; to provide S500MC thermomechanically rolled steels reasonable quotation for products consulted by users within one hour; to provide investigation reception: we guarantee to receive the investigation of users at any time and provide various convenient conditions for users.

Leave a message