S315MC steel for cold forming parts properties, modulus

In 2019, the output of pig iron in the world was 1.265 billion tons, with China accounting for 64%; the overseas output accounted for 36% (460 million tons), ranking 86.982 million tons of EU 28 countries, 74.907 million tons of Japan, 74.099 million tons

In 2019, the output of pig iron in the world was 1.265 billion tons, with China accounting for 64%; the overseas output accounted for 36% (460 million tons), ranking 86.982 million tons of EU 28 countries, 74.907 million tons of Japan, 74.099 million tons of India, 73.264 million tons of CIS, and S315MC steel for cold forming parts 47.521 million tons of South Korea. In the first quarter, the global output was 311 million tons, with a year-on-year decrease of 0.5%, with China S315MC steel for cold forming parts increasing by 2.4%; the overseas output decreased by 5.4%, Among them, EU decreased by 9.2%, Japan increased by 1.3%, India decreased by 7.7%, CIS increased by 2.1%, and South Korea decreased by 4%.

The company adheres to the principle of integrity, standardization and efficiency, wins the market with technology, gains reputation with creative services, and wholeheartedly provides customers with high-quality S315MC steel for cold forming parts, efficient and fast services. Facing the future, adhere to independent innovation.

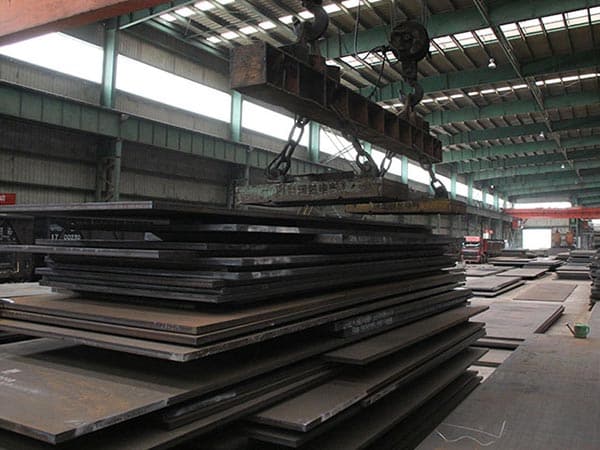

Alloy steel plates that have the ability to develop an extensive range of hardness and strength. Alloying elements and thermal treatments, such as quenching and tempering, greatly influence the hardness and strength of the steel. Welding and forming of this steel plate S315MC steel for cold forming parts should be avoided. It is best utilized wherever high resistance to fatigue and or impact is necessary. We can supply ASTM, JIS, DIN and GB various standards alloy steel grades.

The company's logistics uses third-party logistics. This logistics model plays an important role in improving the efficiency of our business operations. Third-party logistics is an important form of logistics specialization. As a company specializing in logistics, third-party logistics companies have a wealth of experts who specialize in logistics operations, which is conducive to ensuring the professional production of the company, reducing costs, and improving logistics level of the company. Both the customers and the company benefit from the logystics mode.

Composition characteristics of Q420 alloy steel plate: 1.Low carbon: Due to the high requirements for toughness, weldability and cold forming performance, its carbon content does not exceed 0.20%. 2. Add manganese-based alloy elements. 3. Add auxiliary elements such as niobium, titanium or vanadium, which is beneficial to obtain fine ferrite grains and improve the strength and toughness of the Q420 alloy steel, S315MC steel for cold forming parts.

The consistent tenet of honest management! Know the needs of customers, for the needs of customers, urgent customers think! Our quality is better for the S315MC steel for cold forming parts same products, our price is lower for the same quality, and our service is better for the same price. welcome to purchase steel materials from our company. we have the professional team and good after-sale system to customers. our company S315MC steel for cold forming parts is your best choose.

We are willing to cooperate sincerely with you with high-quality S315MC steel for cold forming parts products and sincere service to expand the market and create brilliant! We will work hard to create a first-class steel company and provide you with faster and more considerate after-sales services! Moreover, our shipbuilding steel plates have been certified by the nine countries' classification societies including DNV, ABC, GL, LR, BV, CCS, RINA, NK, and KR. The quality assurance system has passed ISO9001-2000 standard certification.

Leave a message