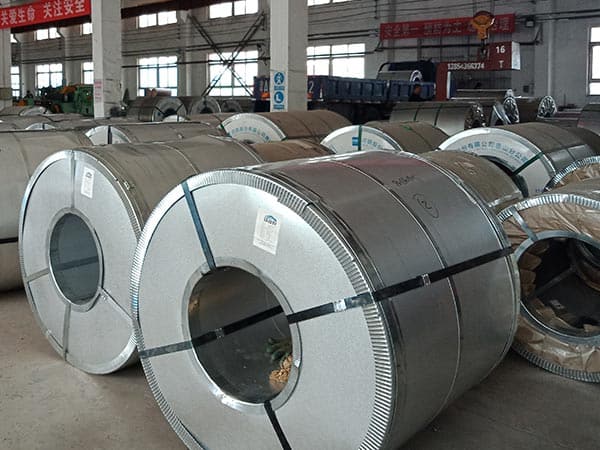

Professional S500MC hot rolled steel for car shell sheet suppliers in China

The company's main business: ship plate, S500MC hot rolled steel for car shell low alloy plate, automobile steel, high-strength plate, pipeline steel, boiler steel plate, weathering plate, wear-resistant plate, bridge plate, pressure vessel plate, st

The company's main business: ship plate, S500MC hot rolled steel for car shell low alloy plate, automobile steel, high-strength plate, pipeline steel, boiler steel plate, weathering plate, wear-resistant plate, bridge plate, pressure vessel plate, steel plate, steel processing, etc. The company takes the implementation of high-end, S500MC hot rolled steel for car shell high-quality, deep processing, strengthening the main business, diversified operation, group operation, enterprise transformation and upgrading as its development strategy, and makes all efforts to be your professional S500MC hot rolled steel for car shell steel supplier and partner.

42CrMo4 material is an alloy structural steel with high strength, high hardenability, good toughness, small deformation during quenching, and high creep strength and endurance strength at high temperatures. 42CrMo4 steel is a modified AISI 4140 steel. The S500MC hot rolled steel for car shell product is mainly used in the manufacturing of seamless hydraulic cylinder or gas cylinder, heavy machinery, cranes, excavators and forklifts, etc.

The wear-resistant layer of S500MC hot rolled steel for car shell wear-resistant steel plate is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are added. The carbide in the microstructure is distributed in the form of fiber, and the direction of the fiber is perpendicular to the surface. The microhardness of carbides can reach hv1700-2000 and HRC58-62 respectively. The alloy S500MC hot rolled steel for car shell carbide has strong stability at high temperature, high hardness and good oxidation resistance. It can be used normally within 500 ℃.

A plasma cutter uses a stream of compressed gas (air, nitrogen, argon, etc.) and a consumable wire electrode as the two primary feedstocks of the steel cutting process. The electrode sends a high electrical charge through the gas, raising its temperature to the point of ionization to generate extremely hot plasma (~20,000°C). This plasma is directed through the cutting tip to create a highly focussed beam, with velocities approaching the speed of sound.

Q355B steel and S500MC hot rolled steel for car shell steelBoth Q345B and Q355B are low alloy steels. The difference is that the yield strength of Q345B low alloy steel and Q345B low alloy steel is different. In Q345B low-alloy steel, q represents the yield strength of this material, and the latter 345 represents the yield value of this material is around 345mpa. Q in Q355B low-alloy steel also represents the yield strength of this material, and the latter 355 indicates that the yield value of this material is around 355mpa.

The company's after-sales service tenet is "customer first, timely guarantee, enthusiastic service and effective work". In order to establish a set of perfect after-sales service system and strict management system, so that the after-sales service can be effectively guaranteed. The company has set up after-sales service department to ensure timely, unique and effective response to every user's request, coordinate internal resources internally, and put an end to all evasion and delay.

Leave a message