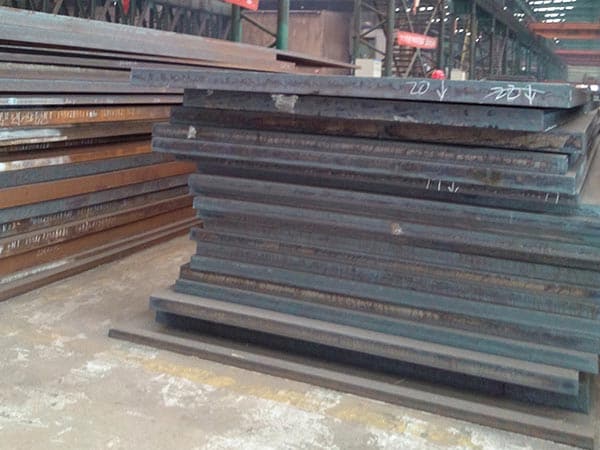

Mild steel material grade B600L steel for car safety parts hardness

After 1975, our equipment includes blast furnaces, electric furnaces, vacuum refining furnaces, and electroslag furnaces. The product varieties are relatively complete. Plates, B600L steel for car safety parts tubes, wires, belts, and profiles have a cert

After 1975, our equipment includes blast furnaces, electric furnaces, vacuum refining furnaces, and electroslag furnaces. The product varieties are relatively complete. Plates, B600L steel for car safety parts tubes, wires, belts, and profiles have a certain scale, including magnetic, elastic, expanded, bimetal and other precision alloy materials for national defense and electronics industries. In 1982, these plants produced 364,000 tons of B600L steel for car safety parts steel and 542,000 tons of steel.

The salesman of the company is familiar with all aspects of knowledge. Understand the company profile: group, company profile, various honor certification, enterprise's functional strength and other advantages analysis. Know the main product brand types and specifications of the company, and know the special knowledge of the product (production process and advantages of the product, simple identification method of product quality, etc.)

Stainless steel plates are alloy steels with very good strength, precision, and toughness, and can be used for many purposes in processing. The surface of the stainless steel plate is smooth and beautiful, and it can be processed into various high-end hardware products. B600L steel for car safety parts, Stainless steel plates have outstanding characteristics and a wide range of applications. Stainless steel plates are used outside of buildings in coastal areas to prevent corrosion. The seawater has strong acidity and alkalinity. General steel plates are prone to rust and corrosion for a long time.

Box making, door-to-door: fill in the packing plan: box making time, ship name, voyage number, customs declaration number, transfer port, destination port, gross weight, number of pieces, volume, door point, contact person, telephone number, etc., and arrange the train shift 1-2 days before the closing date (two days before the ship's date). Internal loading: fill in the packing plan: ship name, voyage number, customs declaration number, transfer port, destination port, gross weight, number of pieces, volume, cabin number, etc., and arrange the train shift 1-2 days before the closing date (two days before the ship's date).

B600L steel for car safety parts, Q390B steel plate generally adopts the process route of refined material entering the furnace-smelting (converter, electric furnace-microalloying treatment-argon blowing-LF refining-low superheat continuous casting (feeding rare earth wire)-controlled rolling and controlled cooling. During smelting, The scrap steel is added to the furnace along with the charge and smelted according to the conventional process. After tapping, the deoxidizer and alloy are added. After the molten steel is treated by argon blowing, it is cast immediately. Rare earth elements are added to the steel, the Q390B steel plate is purified, and the content of inclusions is greatly reduced.

Our company has its own steel plate manufacturing plant, processing plant and steel pipe plant. We can machine the steel according to the B600L steel for car safety parts customer's requirements and meet the customer's requirements. If you want to ask any questions about steel products, please contact us directly. Our customer service staff will give you a detailed answer. If you want to purchase B600L steel for car safety parts steel products, please tell me your specific needs, we have professional business personnel to communicate with you.

Relying on the background of high-quality steel resources and its own strong steel machining capabilities, BBN comany can not only supply various steel material products, such as steel coils, steel plates, B600L steel for car safety parts sheet, steel pipes, and shaped steels, but also provide a variety of steel deep processing services like cutting, welding and grinding. Through continuous technological innovation and after-sales service optimization, the company has its own world on the domestic and international steel industry stage!

Leave a message