How to recognize high quality S700MC automobile structure steel coil

The capital letter H in S355J0H and S355J2H stands for ""Hollow section"", which respectively represents the pipe of S355J0 and S355J2.The Executive Standards of S355J0 steel and S355J2 steel, S700MC automobile structure steel coil are

The capital letter H in S355J0H and S355J2H stands for ""Hollow section"", which respectively represents the pipe of S355J0 and S355J2.The Executive Standards of S355J0 steel and S355J2 steel, S700MC automobile structure steel coil are both EN 10025-2, the difference is that they have different temperature requirements for impact energy: S355J0 - impact energy at 0 ℃ is required to be ≥ 27J. S355J2: impact energy at - 20 ℃ is required to be ≥ 27J.

S700MC automobile structure steel coil and so on steel structure engineering steel has good plasticity, which can make the structure have obvious deformation before being destroyed, so as to avoid brittle failure of structure. The good plasticity of steel can adjust the local peak stress to redistribute the stress, and improve the ductility of components, so as to improve the seismic capacity of the structure. The impact toughness of S700MC automobile structure steel coil and so on steel structure engineering steel is good, which can improve the ability of resisting dynamic load and avoid the occurrence of cracks and brittle fracture.

S355J2 steel plate rolling process is controlled rolling process. In the rolling process, the ingot rolling temperature is 1000-1050℃; in the first stage, the low-speed and large reduction rolling process is adopted, the high-temperature stage is 950-1000℃, the S700MC automobile structure steel coil rolling speed is 1.6-2.0m/s, the single reduction rate is 15-20%, and the cumulative reduction rate is 40-45%, so as to ensure sufficient deformation of ingot. In the first stage, the start rolling temperature is 910-930℃, and the finish rolling temperature is ≤ 870℃.As a basic building material, steel plates are currently widely used in automobiles, shipbuilding, chemical industry, aerospace and other fields. Reasonable selection of flaw detection methods to ensure the quality of S700MC automobile structure steel coil steel plates is of great significance to safe production. Common defects of steel plates are folding, inclusion, shrinkage, air bubbles, delamination and cracks. These problems can be discovered in time through flaw detection.

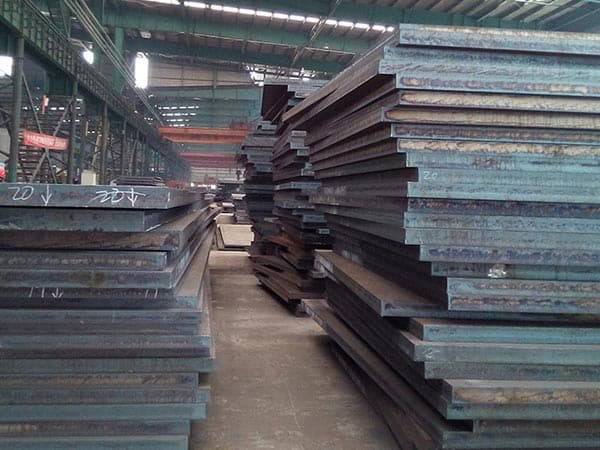

The company will rely on its good reputation, excellent hot-rolled plates, steel pipes, steel structure products, and intimate S700MC automobile structure steel coil after-sales service to customers. I would like to express my heartfelt thanks to the old and new friends and customers who have always given care, support and help to the company! The company sincerely hopes to establish a long-term cooperative relationship with them, mutual benefit and common development. Welcome to come and visit our S700MC automobile structure steel coil steel mill.

Our company regularly visits customers, consults and follows up the after-sales service, and directly solves problems for customers. In the use of our steel materials, whether quality problems or not, the after-sales will help solve the problem as soon as possible. We promise free life-long replacement for any product quality problems. The sound after-sales service system make you free from worries.

Leave a message